PCB Prototype: What Is It and Why You Need One

What is a PCB Prototype? A PCB (Printed Circuit Board) prototype is a preliminary version of a printed circuit board that is used for testing and validation before mass production.

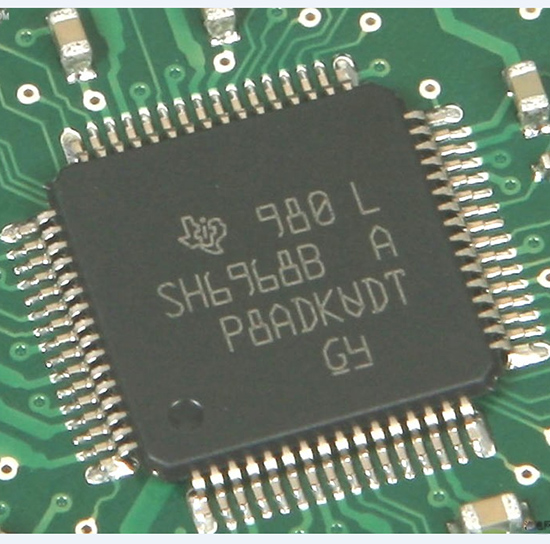

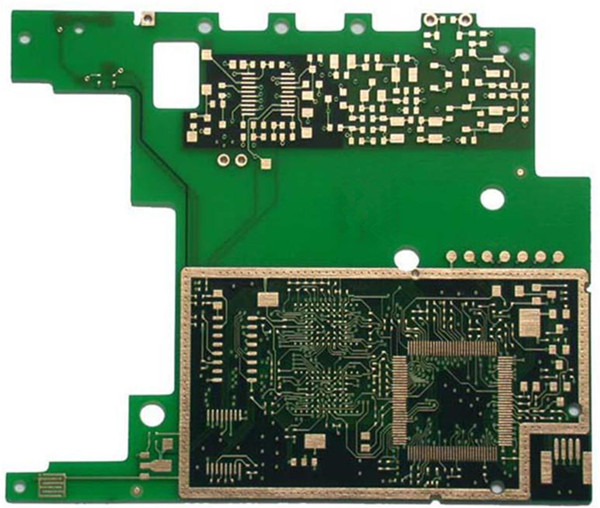

PCB REVERSE ENGINEERING

IC Unlock + PCB Reverse engineering Services - We will crack your IC sample. You will receive IC program in Bin / Hex file for burning any new ICs

PCB to schematic, Schematic to Gerber file, PCBA to Schematic Gerber & Bom List

We focus on a strategy of continuous customer-centric innovation. The goal is to deliver timely solutions for anticipated and actual customer.

We offer our customers from around the world to maintain a very good communication and product support services.

We will reverse engineer your PCB sample, and deilver the engineering file into:1. PCB 2. Gerber File 3. BOM List 4. Schematic Diagram

16 years deep in the reverse analysis of integrated circuit technology, senior technical team, skilled, experienced in a variety of blind buried hole PCB , laser blind hole board, UHF board, ceramic board , component density, all over the microstrip lines and other long lines, high-frequency processing requirements and strict control of electromagnetic compatibility of the communication board copy

All about PCB Reverse Engineering & IC Crack

What is a PCB Prototype? A PCB (Printed Circuit Board) prototype is a preliminary version of a printed circuit board that is used for testing and validation before mass production.

Introduction to Flexible PCBs Flexible Printed Circuit Boards (FPCBs) have gained immense popularity in recent years due to their unique characteristics and versatile applications.

What is a PCB Turnkey Service? A PCB (Printed Circuit Board) turnkey service is a comprehensive solution provided by electronics manufacturing companies that encompasses the entire