One major challenge in the industry is how to replace old-fashioned PCBs utilized in the high-frequency applications.

In order to properly understand the PCB clone service, it is very important that you first have a good understanding of what the PCB clone is what its benefits are, as well as the way it functions

What Does PCB Clone Mean?

PCB clone refers to PCB duplication or PCB copy. This can be described as a reverse technology of research which is based on the already-existing PCB boards, and then make another copy. This refers to PCB reverse engineering’s integrated tasks, IC unlock (which is also called IC cracks), PCB prototyping and debugging, and finally re-production

Furthermore, PCB cloning, which is under that premise that circuit boards and physical objects of electronic products are already available, the reverse technology is utilized in analyzing this circuit board, the initial PCB file of the product, BOM file, the schematic file, other documents like PCB silkscreen and PCB Gerber, in a reverse manner.

More on PCB Clone

For now, some people make use of IC unlock technology to extract the Hex or Bin code from the board’s programmable ICs to ensure the cloned boards would function the same. Also, make use of these production and engineering documents in component soldering, PCB re-production, circuit board debug, flying probe testing, so as to finish up the whole copy of the initial circuit board as a sample.

In addition, hardware engineering can gain many benefits from reverse engineering. This is important for human mapping DNA, as well as computer software development. You can replicate the design of the circuit board by cloning the PCB.

The two major steps when offering a PCB clone service are making the BOM, as well as duplicating its schematics. The clone PCB board works with different research methods to help in the creation of the PCB design circuits for producing high-quality electronic devices. Also, it makes use of the circuit schematics and BOM.

Furthermore, note that the process of PCB cloning could be difficult to grasp. Every day, electronic devices evolve, and many electronics pass through upgrades at least once yearly. Also, many engineers believe that traditional research and development methods won’t be enough to stay at the same pace with electronics replacement evolution.

This is why reverse engineering has become very popular. Redesigning circuit boards using PCB clone is a very cost-effective solution. This helps to extend the life of systems and devices when the components are obsolete.

What are the Benefits of PCB Clone?

Now you understand how PCB clone service works. Now it is important that you understand the benefits that PCB clone offers. PCB clones offer some benefits. Let’s consider them.

Cost-effective and economical option

The manufacturing of PCB boards takes a very long time. This job is a difficult one which states that using high-quality boards is very important. Also, the PCB manufacturers usually face a huge issue. This could be expensive depending on whatever you want to achieve with the printed circuit board.

Designing the PCB boards from scratch is usually much more expensive compared to the duplicates. This covers the cost involved in creating as well as testing the prototypes. Also, the expense involved in adjusting the design parameters, as well as optimization of the design would be incurred as well.

A cost-effective method is PCB cloning. This is because the process of PCB manufacturing will become cost-effective. Also, selecting a PCB replica ensures that you won’t have to spend any money on the design.

Also, it has been revealed that products that come from reverse engineering are usually more superior compared to those manufactured with the use of traditional methods.

Streamlined Production

With PCB cloning, manufacturers can make their circuit boards using less effort. With reverse engineering, you will be able to identify some great designs. Also, manufacturers will be able to combine these designs and start manufacturing the printed circuit boards with respect to the new one.

Furthermore, this strategy helps in automating manufacturing processes and therefore, streamlines the production activities. Also, there will be a reduction in manual labor by simplification and automation. This saves money you should have spent on labor.

In addition, streamlining these processes helps in the manufacturing of long-lasting and high performance boards, thereby boosting the quality of the product.

Engineering technique with great detail

This has to do with paying close attention to all the details (no matter how small) during the board construction. Whenever the company relies on the PCB clones heavily, then it has to investigate this particular board thoroughly. This allows the engineers to produce products and goods with high quality.

In addition, engineers can utilize this technology in creating stable and reliable printed circuit boards in different temperatures. This engineer can utilize the PCB clone in creating products which fits the people’s needs. During the use of reverse engineering, engineers are usually limited to existing circuit board designs. This is why the engineers usually have the motivation and zeal to increase the performance of the product.

Improved freedom and scalability

One benefit of this technology is that companies offering PCB clone service offer much flexibility. This allows them to be very adaptable all through the process of manufacturing. This is why the resulting PCBs are personalized as well as adjusted so as to meet the consumers’ needs.

Furthermore, with PCB cloning, manufacturers can create many boards from one PCB design. This is why they have the ability to create many clone PCB boards. Also, they help in enhancing the processes of companies offering PCB clone service to meet the needs of customers. In addition, manufacturers will be able to earn and make more money.

In addition, with reverse engineering, producers can align their operations for manufacturing with the existing designs of the users. This is why users will be able to specify market requirements as well as place orders. With PCB cloning, both the manufacturers offering PCB clone service and users gets some benefits.

What are the Basic Steps in PCB Cloning?

When receiving a printed circuit board, write down the location, specifications, and type of the component, including the IC gap direction, triplet, and diodes. Furthermore, it is advisable to snap two pictures of the location of the components using any digital camera. Today, PCB boards are becoming very sophisticated compared to diode triodes.

Now, take out all the components found in the PAD holes and the tin. Next, use ultrasonic waves for cleaning the empty circuit boards and then place them inside the scanner. Now, note that you must scan the PCB horizontally and then straightly, else you will not be able to make use of your scanned images.

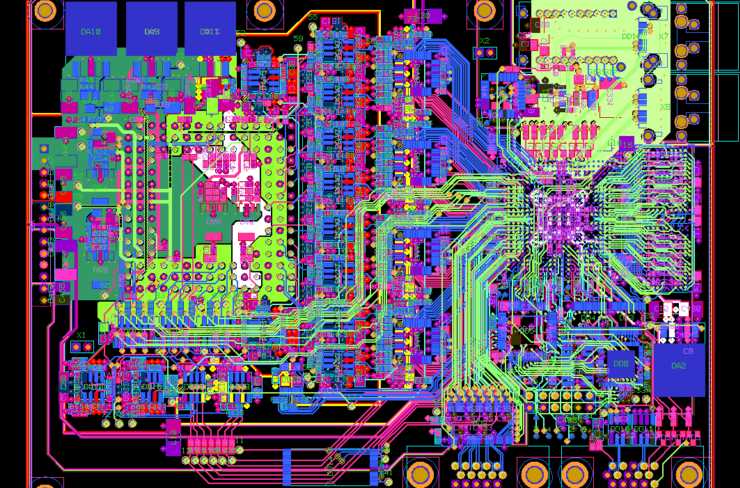

Then, go to Photoshop and open it and then drag the scanner to the program. Imagine its resolution stands at 600 DPI, now the method for the top-screen printing is the same as that of the bottom screen-printing. This makes use of the color sweep and then saves its custom name.

Making use of water yarn paper, polish both the bottom and the top layer till your copper film starts shining. Now, place it inside the scanner and then open Photoshop. Now, color-sweep both layers. Take note that you must place the printed circuit board straight and horizontally into the scanner.

Next, adjust the contrast, darkness, and lightness of the canvas to ensure that the sections with the copper film and those that don’t have strong contrasts convert the secondary image to white and black and then verify to see if there are clear lines. Repeat this process, if the lines are not clear. However, if the image comes out clear, save it in black and white and in BMP file format. In addition, it is possible to make use of Photoshop in restoring and correcting the image to see if there are any flaws.

Now, transform each BMP file to Protel files. For Protel, try to create two levels. Also, if the VIA and PAD are in one place through the layers, the initial stages would be correctly completed. This is why clone PCB board is a great task that requires patience, because minor issues could degrade the matching degree and quality after the clone PCB board copying. Next, convert the BMP of the top layers to the BMP of the bottom layer.

Also, take note of the silk layer (which is yellow in color) on the printed circuit board. After this trace the line found in the TOP layer, then install your device. Once you are done drawing, delete that silk layer. Remember that once you decide to go with PCB duplication, then you will save the cost of paying for the design.

What is the Legal Boundary of Offering a PCB Clone Service?

Regarding PCB cloning, there are some legal considerations you need to take note of. PCB cloning is usually subject to those intellectual property regulations and laws as the initial design. This is why it is very important that manufacturers of clone PCB boards comply with all the applicable regulations and laws.

Copyright infringement

When you create a printed circuit board, you have rights to the board’s design and so anyone that copies or replicates it without your approval can lead to copyright infringement.

Trademark infringement

This happens when you have already registered a particular trademark for your circuit board and then someone decides to produce one looking very similar to yours

Patent

This happens when you have already submitted your PCB design’s patent application and then a manufacturer offering PCB clone service copies it. However, note that the patent will not protect a PCB’s functional design. This only covers the shape and form of the product.

Trade Secret Law

This comes into play when you utilize a trade secret in designing and building the PCB, and then a company offering clone PCB boards decides to clone it without your authorization or knowledge.

How Does PCB Cloning Help in the Redesigning and Development of PCBs

PCB clone makes use of different reverse techniques in order to obtain a design, BOM, and circuit schematic for your existing electronic designs. The development of new products that would have taken between two to three years will now take just a few months using reverse engineering.

In the last ten years, electronic technology development has been experiencing great changes. This is why future updates of electronic products may come faster. Many electronics engineers believe that the use of traditional research and development methods can’t meet up with the quick steps involved in the replacement of modern electronics.

Also, because there are many designs in the ,marketplace, with reverse engineering is a quick approach for engineers to adopt to meet up with the marketplace as well as meet the top runners

Why Getting a PCB Clone Service is Important

Using a PCB clone service means that you can generate replicas of electronic circuit boards. Making any PCB replica isn’t an easy task. Cloning has to be your last resort if the circuit comes with a reliable controller.

With PCB cloning, you can generate more PCBs without having to design them from the start. This is why they are very important in the electronics of today. PCB clone is now more popular among the manufacturers of electronics to serve as a cost-effective alternative.

PCB copying is a very effective way to ensure that multiple copies are created during the process of PCB production. You might have to create multiple boards to help with product testing, build boards just for bulk production, and create some sample boards for your customers. In each of the cases outlined above, PCB clone will easily create whatever number of boards you desire and with less or minimal effort.

Conclusion

Getting a PCB clone service is very important because of the benefits it offers. Asides saving you the stress of creating new designs or starting from the scratch, you can create multiple copies within a short time frame, all at a reduced cost.