Introduction to PCB Manufacturing

Printed Circuit Board (PCB) manufacturing is a crucial process in the electronics industry. It involves the creation of a board that connects electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate. PCBs are used in almost all electronic devices, from smartphones and computers to industrial equipment and medical devices.

Types of PCB Manufacturing

There are several types of PCB manufacturing, each with its own advantages and disadvantages. The most common types are:

| Type | Description |

|---|---|

| Single-sided PCB | A PCB with conductive tracks on one side only. Suitable for simple circuits. |

| Double-sided PCB | A PCB with conductive tracks on both sides. Provides more space for components and allows for more complex circuits. |

| Multi-layer PCB | A PCB with multiple layers of conductive tracks separated by insulating layers. Allows for even more complex circuits and higher component density. |

| Flexible PCB | A PCB made from flexible materials that can be bent or folded. Useful for applications where space is limited or the PCB needs to conform to a specific shape. |

| Rigid-flex PCB | A combination of rigid and flexible PCBs. Provides the benefits of both types in a single board. |

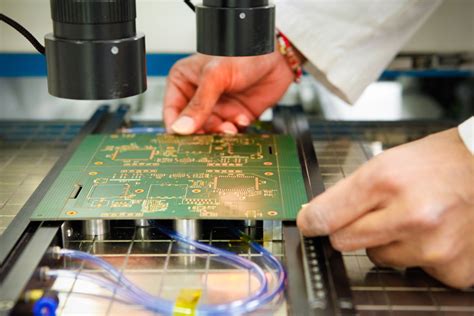

PCB Manufacturing Process

The PCB manufacturing process involves several steps, each of which must be carried out with precision to ensure the quality and reliability of the final product.

Step 1: Design and Layout

The first step in PCB manufacturing is to design the circuit and create a layout of the PCB. This is typically done using specialized software such as Altium Designer or Eagle. The layout includes the placement of components, the routing of conductive tracks, and the creation of any necessary holes or cutouts.

Step 2: Printing the Circuit Pattern

Once the layout is complete, the next step is to print the circuit pattern onto the PCB substrate. This is typically done using a photoresist process. The substrate is coated with a light-sensitive material and then exposed to light through a photomask that contains the circuit pattern. The exposed areas of the photoresist harden, while the unexposed areas can be washed away.

Step 3: Etching

After the photoresist has been developed, the PCB is placed in an etching solution that removes the copper from the areas not protected by the hardened photoresist. This leaves behind the conductive tracks and pads that make up the circuit.

Step 4: Drilling

Once the etching is complete, any necessary holes are drilled into the PCB. These holes may be used for mounting components or for connecting different layers of the board.

Step 5: Plating

After drilling, the PCB is plated with a thin layer of copper to improve conductivity and protect the exposed copper from oxidation. Additional plating with nickel and gold may also be applied for improved durability and solderability.

Step 6: Solder Mask and Silkscreen

A solder mask is then applied to the PCB to protect the copper tracks from short circuits and oxidation. This is typically a green or blue color. A silkscreen layer is also applied to the board to add labels, logos, and other markings.

Step 7: Surface Finish

Finally, a surface finish is applied to the exposed copper areas of the PCB to protect them from oxidation and improve solderability. Common surface finishes include Hot Air Solder Leveling (HASL), Organic Solderability Preservative (OSP), and Electroless Nickel Immersion Gold (ENIG).

Advantages of PCB Manufacturing Services

Using a professional PCB manufacturing service offers several advantages over in-house production or DIY methods.

Quality and Reliability

Professional PCB manufacturers use state-of-the-art equipment and follow strict quality control procedures to ensure that every board meets the highest standards of quality and reliability. They have the expertise and experience to identify and correct potential issues before they become problems.

Cost Efficiency

While it may seem more cost-effective to produce PCBs in-house, the reality is that professional PCB manufacturing services can often provide a more cost-efficient solution in the long run. They have the economies of scale to purchase materials in bulk and the automation to reduce labor costs.

Faster Turnaround Times

PCB manufacturing services have streamlined processes and dedicated production lines that allow them to produce boards quickly and efficiently. This can be especially important for projects with tight deadlines or for businesses that need to get products to market quickly.

Access to Advanced Technologies

Professional PCB manufacturers invest in the latest technologies and equipment to stay competitive. This means that they can offer advanced features and capabilities that may not be available with in-house production, such as high-density interconnect (HDI) boards or advanced surface finishes.

Choosing a PCB Manufacturing Service

When choosing a PCB manufacturing service, there are several factors to consider to ensure that you get the best possible results for your project.

Experience and Expertise

Look for a PCB manufacturer with a proven track record of success and expertise in the specific type of board you need. Ask for references and examples of previous work to ensure that they have the necessary skills and experience.

Quality Control Procedures

Quality control is critical in PCB manufacturing. Ask about the manufacturer’s quality control procedures and certifications, such as ISO 9001 or UL listing. Make sure that they have a robust testing and inspection process in place to catch any defects or issues before the boards are shipped.

Turnaround Time and Pricing

Consider the manufacturer’s turnaround time and pricing structure. While it may be tempting to choose the cheapest option, keep in mind that quality and reliability should be the top priorities. Look for a manufacturer that can provide a balance of speed, quality, and affordability.

Customer Service and Support

Finally, consider the level of customer service and support offered by the manufacturer. Look for a company that is responsive to your needs and willing to work with you to ensure that your project is a success. Good communication and a partnership approach can go a long way in ensuring a smooth and successful PCB manufacturing process.

Frequently Asked Questions

What is the minimum order quantity for PCB manufacturing?

The minimum order quantity (MOQ) for PCB manufacturing can vary depending on the manufacturer and the specifics of your project. Some manufacturers may have MOQs as low as one or two boards, while others may require a minimum of 100 or more. Be sure to discuss your needs with the manufacturer upfront to ensure that they can accommodate your order.

How long does PCB manufacturing typically take?

The turnaround time for PCB manufacturing can vary depending on the complexity of the board, the manufacturer’s workload, and other factors. Simple boards may be produced in as little as 24 hours, while more complex boards may take several weeks. Be sure to discuss your timeline with the manufacturer upfront and plan accordingly.

What file formats are needed for PCB manufacturing?

Most PCB manufacturers require Gerber files, which are a standard format used in the electronics industry. Gerber files contain all the necessary information for manufacturing the board, including the copper layers, drill holes, and silkscreen. Some manufacturers may also accept other formats such as ODB++ or IPC-2581.

Can I request a prototype before placing a full order?

Yes, most PCB manufacturers offer prototyping services that allow you to test and validate your design before committing to a full production run. This can be a valuable step in ensuring that your board meets your specific needs and requirements.

What certifications should I look for in a PCB manufacturer?

There are several certifications that can indicate a PCB manufacturer’s commitment to quality and reliability. These include ISO 9001 for quality management systems, UL listing for safety, and RoHS compliance for environmental sustainability. Ask the manufacturer about their certifications and what they mean for your specific project.

Conclusion

PCB manufacturing is a complex and highly specialized process that requires expertise, precision, and attention to detail. By understanding the basics of PCB manufacturing and working with a reputable PCB manufacturing service, you can ensure that your electronic projects are successful and reliable.

When choosing a PCB manufacturing service, look for a company with experience, expertise, and a commitment to quality. Consider factors such as turnaround time, pricing, and customer service, and don’t hesitate to ask questions or request prototypes to ensure that your needs are met.

With the right PCB manufacturing partner, you can bring your electronic ideas to life and create products that are innovative, reliable, and successful in the marketplace.