Key Components of a Drone Control Board

A typical drone main board integrates the following core subsystems:

- Flight controller (FC)

- Electronic speed controllers (ESCs)

- Radio control receiver

- Telemetry radio

- GPS module

- Power distribution board (PDB)

- Sensors (accelerometer, gyro, barometer, etc.)

Let’s examine each of these components in more detail.

Flight Controller

The flight controller is the main processor that runs the software responsible for controlling the drone’s motion and stabilization. It takes inputs from the radio receiver, onboard sensors, and any autonomous navigation systems, and sends corresponding control signals to the ESCs and motors.

Some of the most popular open source flight controller firmware options include:

| Firmware | Description |

|---|---|

| Ardupilot | Powerful, highly configurable autopilot supporting many vehicle types |

| Betaflight | Optimized for smooth, responsive flight characteristics in racing/freestyle drones |

| PX4 | Professional grade autopilot with wide range of advanced features |

| INAV | Navigation-focused firmware with good GPS integration |

Choosing the right flight controller and firmware depends on the specific requirements and goals for your custom drone build.

Electronic Speed Controllers

ESCs are responsible for converting the low current control signal from the flight controller into the high current 3-phase AC power that drives the brushless motors. For a quadcopter, 4 ESCs are required, one for each motor. Larger designs like hexacopters and octocopters will require 6 or 8 ESCs respectively.

The key factors to consider when selecting ESCs are:

– Maximum continuous current rating

– Supported protocols (PWM, Oneshot, Multishot, DShot, etc.)

– Size and weight

– Programmability

Ensuring the ESCs are appropriately sized for the motor stator size and propeller dimensions is critical. Overloaded ESCs can overheat and fail, potentially causing a dangerous crash.

Radio Control Receiver

The radio receiver allows the drone to be controlled remotely by the pilot. It communicates with the hand-held transmitter and translates the control stick inputs into signals that are fed into the flight controller. This is what enables real-time flying and maneuvering of the drone.

The most common frequencies for RC drone control are:

– 2.4 GHz

– 433 MHz (for long range)

– 900 MHz (for long range)

There are also various communication protocols used between the transmitter and receiver, such as:

– PWM

– PPM

– SBUS

– iBUS

Many receivers now support multiple protocols, making them compatible with a wider range of transmitters. This is helpful as it allows more flexibility and options when choosing a controller.

Telemetry Radio

In addition to the main RC link, most drones also incorporate a separate telemetry radio system. This allows for real-time transmission of flight data from the drone back to the pilot’s ground station. Common telemetry data includes:

– Battery voltage and current draw

– GPS coordinates and altitude

– Flight controller status

– Sensor readings

– Informational messages and error codes

Having access to this live data stream can be extremely valuable when monitoring the health and performance of the drone in flight. It provides an early warning if something starts to go wrong, potentially allowing the pilot to take corrective action before a failure occurs.

Some of the most widely used telemetry systems are:

– 3DR Radio

– DragonLink

– FrSky

– LightTelemetry

– XBee

The choice of telemetry system will depend on the desired range, data bandwidth, and compatibility with other components.

GPS Module

For any autonomous or assisted flight modes, a GPS module is a must. It provides the drone with accurate position and velocity data that can be used for navigation and stabilization. Standard GPS is accurate to within a few meters, but some higher end modules can achieve centimeter level precision by using Real Time Kinematic (RTK) techniques.

Important considerations when choosing a GPS module include:

– Satellite constellations supported (GPS, GLONASS, BeiDou, Galileo)

– Update rate

– Horizontal and vertical position accuracy

– Time to first fix

– Size and weight

Typically the GPS will connect to a dedicated port on the flight controller, and may also require a separate power supply. The FC firmware will have specific configuration settings for adjusting the GPS parameters.

Power Distribution Board

The PDB is responsible for taking the battery voltage and safely distributing it to the ESCs and other components. It also often includes power filtering capacitors, voltage regulators for 5V and 12V peripherals, and current sensing for battery monitoring.

Key design considerations for the PDB include:

– Maximum total current capability

– ESC power connectors

– Additional auxiliary power connectors

– Voltage regulators

– Current sensor

– Size and layout

Some PDBs may also include the battery eliminator circuit (BEC) used to power the FC, receiver, and servos. However, many builders prefer to use separate standalone BEC modules for improved reliability.

Sensors

In order to fly stably, the drone needs to have accurate data about its orientation and motion. This is where the onboard sensor suite comes in. The core sensors found on most flight controllers include:

| Sensor | Function |

|---|---|

| Accelerometer | Measures linear acceleration forces, used for determining orientation |

| Gyroscope | Measures angular velocity, used for tracking rotation |

| Barometer | Measures air pressure, used for altitude hold |

| Magnetometer | Measures Earth’s magnetic field, used as a compass for navigation |

By fusing the data from these different sensors, the flight controller can determine the drone’s absolute orientation in space. This is crucial for self-leveling and executing autonomous maneuvers.

Additional sensors that may be helpful for more advanced applications include:

- Optical flow camera

- Laser rangefinder

- Ultrasonic rangefinder

- Precision landing beacon detector

The choice of sensors will be dependent on the specific use case and performance requirements for the drone.

Choosing a Flight Controller

With so many different flight controllers on the market, it can be difficult to know where to start. Here are some key factors to consider when making a selection:

Microprocessor

The “brain” of the flight controller is the main processor chip. It needs to be fast enough to run the stabilization loops and navigation algorithms in real-time. Some common choices are:

- STM32F4

- STM32F7

- STM32H7

In general, the higher the processor speed, the better the flight performance will be. However, this also comes at the cost of increased power consumption and heat generation.

Firmware Compatibility

In order to actually fly, the hardware needs to be loaded with compatible firmware. It’s important to check that the flight controller supports the desired firmware and version.

For example, Betaflight is optimized for STM32F4 and STM32F7 based controllers. It will not run on an STM32F3 board. Similarly, a newly released FC may not yet be supported by an older firmware version. Always consult the documentation and compatibility charts before making a purchase.

Form Factor

Flight controllers come in a range of different physical form factors. Some of the most common are:

- 30.5mm x 30.5mm (standard size)

- 20mm x 20mm (mini size)

- 16mm x 16mm (micro size)

Smaller sizes can be advantageous for tight builds, but may sacrifice features or expandability. It’s also important to consider the mounting hole layout and stack height when selecting a form factor.

Sensor Suite

As discussed earlier, the onboard sensors are a key part of any flight controller. Higher end FCs will often use more sophisticated sensors with better noise performance and temperature stability.

Some controllers come with barometer and magnetometer sensors built-in, while others will require external modules to be connected. Consider the specific needs of your build when deciding which sensors are required.

Connectivity

Pay close attention to the types and number of ports available on the FC. Ensure that there are enough connections for all the peripherals you plan to use, such as:

- RC receiver

- ESCs

- GPS

- Telemetry

- Blackbox logging

- Additional sensors

- LED strip

- Buzzer

- etc.

If the FC doesn’t have enough ports, you may need to use breakout boards, splitters, or other adapters. This can add complexity and points of failure to the wiring.

Price

Of course, budget is always a consideration in any project. Flight controller prices can range from around $20 for a basic model up to $200 or more for high end units.

In general, you get what you pay for. More expensive controllers will offer better performance, more features, and higher quality components. However, it’s not always necessary to go for the top of the line option. Many cheaper FCs are still perfectly capable of delivering great flight characteristics.

The key is to strike a balance between price and performance that makes sense for your specific needs. Don’t overspend on features you’ll never use, but also don’t skimp too much on quality or you may end up regretting it later.

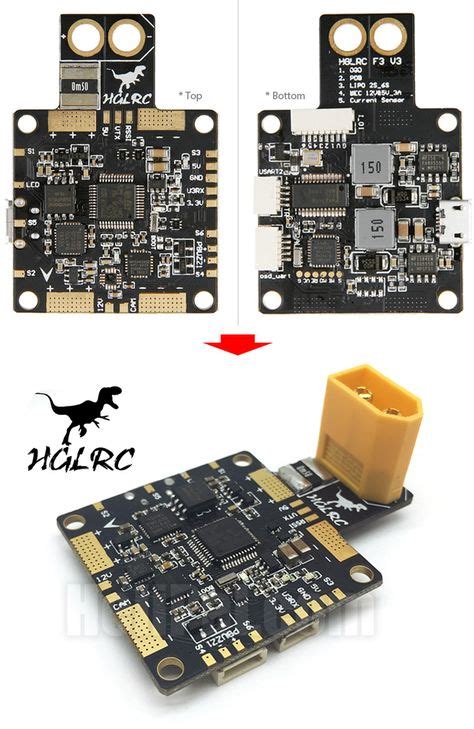

Integrated vs Modular Design

One important decision when designing a custom drone is whether to go with an integrated or modular architecture. An integrated approach combines the FC, ESCs, PDB, and sometimes even the RC receiver into a single PCB. A modular design uses separate boards for each function, which are then wired together.

Integrated Pros:

- Simpler wiring with fewer connections

- Lighter weight

- More compact

- Lower cost

Integrated Cons:

- Limited upgrade options

- Harder to repair/replace individual components

- Less flexibility in component choice

Modular Pros:

- Easily upgradeable

- Components can be swapped out as needed

- More customization options

- Damaged components can be replaced individually

Modular Cons:

- More complex wiring with more failure points

- Heavier

- Physically larger

- Higher cost

The best approach depends on the specific goals and constraints of the build. An integrated design may be preferred for a racing drone where every gram counts. A modular approach may be better for a large photography platform where easy maintenance is important.

Firmware Options

As mentioned previously, there are several different firmware options available for drone flight controllers. Each has its own strengths, weaknesses, and unique features. Let’s take a closer look at some of the most popular choices.

Ardupilot

Ardupilot is a powerful open source autopilot system that can control almost any type of vehicle, from multirotors to fixed wing planes to cars and boats. It has a wide range of advanced features and customization options.

Some of the key capabilities include:

– Waypoint navigation

– Mission planning

– Autonomous landing

– Camera control

– Follow-me mode

– Geofencing

– Acro/stabilize/loiter/guided/auto flight modes

Ardupilot is a great choice for anyone looking to build a fully autonomous drone for mapping, surveying, or other professional applications. It does have a bit of a learning curve, but the extensive documentation and active community make it relatively easy to get started.

Betaflight

Betaflight is a popular firmware choice for FPV racing and freestyle drones. It is known for its exceptional flight performance and responsiveness. The firmware is highly optimized for fast control loops and low latency.

Some standout features of Betaflight include:

– Oneshot/Multishot/DShot ESC protocols for faster motor updates

– Configurable PID controllers for fine-tuning flight behavior

– Blackbox logging for recording high-rate flight data

– Dynamic filters for smoother motor control

– Configurable stick commands and mode switches

While Betaflight is an excellent performer, it can be a bit daunting for new users. The sheer number of settings and options can be overwhelming. It’s recommended to start with one of the prebuilt configuration files and only make small tweaks until you’re more comfortable with the system.

PX4

PX4 is another popular open source autopilot firmware. It is designed for professional and industrial applications that require maximum reliability and safety. Some of the key features include:

- Extensive sensor compatibility, including RTK GPS and precision landing

- Advanced computer vision integration

- Detailed system monitoring and logging

- Simulation-in-Hardware and Software-in-the-Loop testing

- Modular architecture for easy customization

PX4 is trusted by many commercial drone companies and has been used in a wide variety of applications from delivery to search and rescue. It is a great choice for anyone building a mission-critical platform that needs to meet high standards of safety and reliability.

However, it is overkill for most hobbyist projects. The advanced features and complex architecture come at the cost of increased resource requirements and configuration complexity.

INAV

INAV is an autopilot firmware that is specifically designed for GPS-guided autonomous flight. It includes a variety of advanced navigation modes and sensor integrations.

Some of the standout features of INAV include:

- Excellent GPS performance for position hold and waypoint navigation

- Dedicated modes for aerial photography like position hold and waypoint missions

- Robust failsafe logic with configurable actions

- Compatibility with a wide range of sensors including optical flow and laser rangefinders

INAV is a good choice for anyone building a drone for autonomous photography or videography. The navigation modes make it easy to capture smooth, stable footage without needing expert flying skills.

Like Ardupilot, it has a bit of a learning curve but is generally easier to configure than PX4. The documentation and community support are also very good.

FAQ

What is the best flight controller for a beginner?

For someone just starting out, it’s recommended to choose a FC with well-established firmware like Betaflight or INAV. Look for a controller with built-in sensors, a well-documented feature set, and good community support. Popular beginner-friendly options include the Matek F405, Omnibus F4, and Kakute F7.

How important is vibration isolation for the flight controller?

Proper vibration isolation is critical for preventing “noise” in the accelerometer and gyro data. This can lead to poor flight performance, “twitches”, and even complete loss of control. Always use high quality soft-mount grommets or standoffs to decouple the FC from frame vibrations. For especially noisy setups, an additional vibration-dampening plate may be necessary.

What are the differences between F1, F3, F4, and F7 processors?

The number designation for STM32 processors indicates the relative performance and capability. F1 is the oldest and slowest, while F7 is the newest and fastest. F3 and F4 are in between. In general, it’s best to select the most recent processor that is compatible with the desired firmware.

Can I use a flight controller with a built-in PDB?

Yes, there are many all-in-one flight controllers that integrate the PDB functionality. This can simplify wiring and reduce weight. However, it’s important to check that the power handling capabilities are sufficient for your motor and ESC combination. Also, consider that if either the PDB or FC fails, the entire board will need to be replaced.

What is the advantage of using an external magnetometer?

Many lower cost flight controllers have the magnetometer sensor built-in. However, this can be problematic as the nearby electrical currents from the motors and ESCs can interfere with the magnetic field readings. This can lead to poor yaw stability and inaccurate heading hold. Using an external magnetometer that is mounted away from the electronics can provide much better performance in these cases.

Conclusion

The flight controller is the core of any custom drone build. It serves as the central hub that integrates all the various components and subsystems. When designing a drone from scratch, it’s important to choose a FC that is well-suited to the specific goals and requirements of the project.

By understanding the key elements that go into a flight controller, you can make informed decisions about processor performance, sensor selection, firmware options, and physical form factor. It’s also important to consider whether an integrated or modular architecture makes more sense for your application.

Ultimately, the perfect flight controller will depend on a variety of factors. But by carefully evaluating the options and tradeoffs, you can design a system that delivers the capabilities and performance you need to bring your custom drone vision to life.