What items can be reverse-engineered?

Consumer Electronics

One of the most popular categories of items to reverse engineer is consumer electronics. This includes devices like smartphones, tablets, laptops, smart home gadgets, and wearable technology. By disassembling these products and examining their internal components and circuitry, engineers and hobbyists can gain valuable insights into how they work.

Some reasons to reverse engineer consumer electronics include:

– Understanding the underlying technology and design principles

– Identifying potential security vulnerabilities or exploits

– Developing compatible accessories, peripherals, or software

– Creating clones or knockoff versions of popular products

– Repairing or modifying devices for custom applications

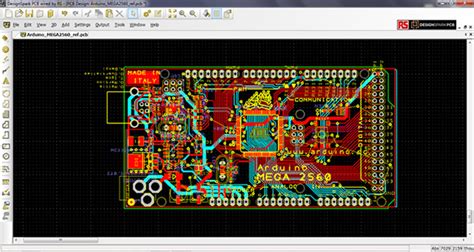

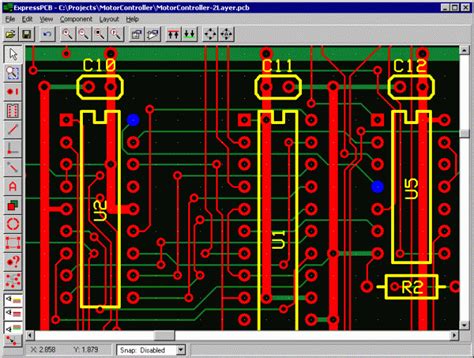

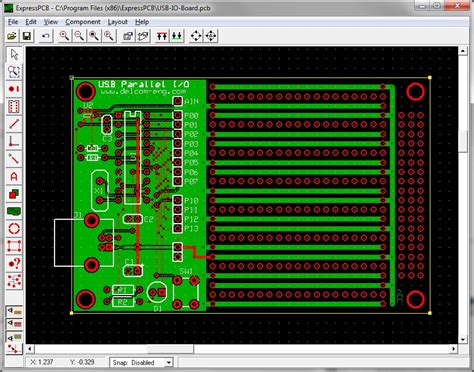

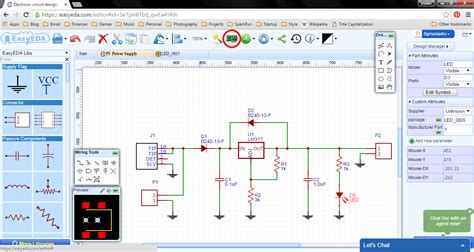

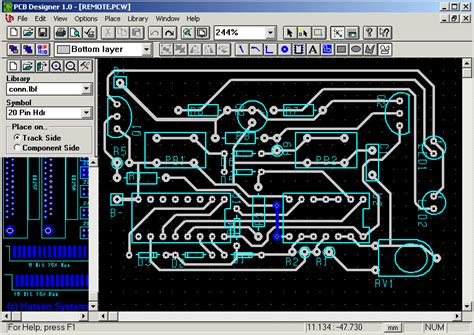

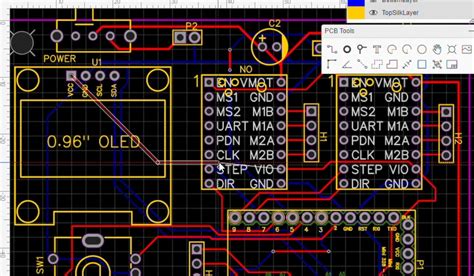

The process of Reverse Engineering consumer electronics typically involves several steps:

- Disassembly – Carefully taking apart the device to access its internal components

- Documentation – Taking photos and notes on the layout, components, and connections

- Schematic Capture – Creating a detailed diagram of the circuitry and components

- Analysis – Examining the components and circuitry to understand their functions

- Prototyping – Building a working replica or modified version of the device

- Testing & Refinement – Testing the prototype to ensure it functions properly and making any necessary adjustments

Some examples of consumer electronics that are frequently reverse-engineered include:

| Device | Reason for Reverse Engineering |

|---|---|

| iPhone | Creating unofficial repair guides, developing 3rd-party accessories |

| Fitbit | Analyzing fitness tracking algorithms, building custom apps |

| Nest Thermostat | Integrating with home automation systems, improving energy efficiency |

| Bluetooth Headphones | Developing compatible audio codecs, enhancing sound quality |

While reverse engineering consumer electronics can be a challenging and time-consuming process, it offers valuable opportunities for learning, innovation, and customization. However, it’s important to be aware of any legal or intellectual property considerations, as some companies may object to their products being reverse-engineered or modified.

Mechanical Devices

Another common category of Reverse-engineerable items is mechanical devices. This includes everything from simple tools and appliances to complex machinery and vehicles. By disassembling and analyzing these devices, engineers can learn how they work and identify opportunities for improvement or customization.

Some reasons to reverse engineer mechanical devices include:

– Understanding the design principles and mechanical systems involved

– Identifying potential failure points or maintenance requirements

– Developing compatible replacement parts or accessories

– Creating custom modifications or adaptations for specific applications

– Improving performance, efficiency, or durability

The process of reverse engineering mechanical devices is similar to that of consumer electronics, but with a greater emphasis on physical components and mechanisms:

- Disassembly – Taking apart the device to access its internal components and mechanisms

- Documentation – Taking photos and measurements of each component and assembly

- 3D Modeling – Creating detailed CAD models of the components and assemblies

- Analysis – Examining the mechanical systems and identifying their functions and interactions

- Prototyping – Fabricating replica or modified components, often using 3D printing or CNC machining

- Testing & Refinement – Assembling the prototype and testing it to ensure proper function and fitment

Some examples of mechanical devices that are often reverse-engineered include:

| Device | Reason for Reverse Engineering |

|---|---|

| Automotive Components | Developing aftermarket replacement parts, improving performance |

| Industrial Machinery | Creating custom tooling or automation systems, increasing efficiency |

| Medical Devices | Analyzing mechanisms and materials, ensuring safety and reliability |

| Aerospace Components | Optimizing strength-to-weight ratios, improving fuel efficiency |

Reverse engineering mechanical devices requires a solid understanding of mechanical principles, materials science, and manufacturing processes. It also often involves the use of specialized tools and equipment, such as 3D scanners, CAD software, and CNC machines.

Software and Firmware

In addition to physical products, software and firmware are also common targets for reverse engineering. This involves analyzing the code and logic of a program to understand how it works and identify potential vulnerabilities or opportunities for modification.

Some reasons to reverse engineer software and firmware include:

– Understanding the algorithms and logic used in the program

– Identifying security vulnerabilities or exploits

– Developing compatible plugins, extensions, or integrations

– Creating interoperability between different systems or platforms

– Modifying or customizing the behavior of the software

The process of reverse engineering software and firmware typically involves several steps:

- Decompilation – Converting the compiled binary code back into a human-readable format

- Analysis – Examining the decompiled code to understand its structure, functions, and logic

- Debugging – Using debuggers and other tools to step through the code and observe its behavior

- Modification – Making changes to the code to alter its functionality or add new features

- Recompilation – Compiling the modified code back into a binary format

- Testing – Running the modified software to ensure it functions as intended

Some examples of software and firmware that are frequently reverse-engineered include:

| Software | Reason for Reverse Engineering |

|---|---|

| Operating Systems | Developing custom drivers or kernels, analyzing security features |

| Embedded Firmware | Customizing device behavior, adding new functionality |

| Proprietary Algorithms | Understanding the underlying logic, developing compatible implementations |

| Legacy Software | Migrating to modern platforms, ensuring compatibility with newer systems |

Reverse engineering software and firmware requires strong programming skills and familiarity with a variety of tools and techniques, such as disassemblers, debuggers, and hex editors. It also often involves working with low-level languages like assembly and navigating complex code structures.

Conclusion

Reverse engineering is a powerful tool for understanding, replicating, and improving a wide range of products and systems. From consumer electronics and mechanical devices to software and firmware, almost anything can be reverse-engineered with the right skills, tools, and techniques.

While reverse engineering can be a challenging and time-consuming process, it offers valuable opportunities for learning, innovation, and customization. By analyzing how things work and identifying opportunities for improvement, reverse engineers can create new products, enhance existing ones, and push the boundaries of what’s possible.

However, it’s important to approach reverse engineering with caution and respect for intellectual property rights. Many companies invest significant resources into developing their products, and may object to having their designs copied or modified without permission. As such, it’s crucial to carefully consider the legal and ethical implications of reverse engineering before embarking on any projects.

Ultimately, the key to successful reverse engineering is a combination of technical skill, creative problem-solving, and a deep curiosity about how things work. Whether you’re a professional engineer, a hobbyist tinkerer, or just someone who likes to take things apart and see what makes them tick, reverse engineering offers endless opportunities for learning and discovery.

Frequently Asked Questions

Is reverse engineering legal?

The legality of reverse engineering depends on the specific circumstances and jurisdiction. In many cases, reverse engineering is protected under fair use doctrines or other legal provisions, especially if it’s done for the purposes of interoperability, education, or research. However, some companies may object to their products being reverse-engineered, especially if the results are used to create competing products or circumvent security measures. It’s important to carefully consider the legal implications of reverse engineering before proceeding with any projects.

What tools are used for reverse engineering?

The tools used for reverse engineering vary depending on the type of item being analyzed. For consumer electronics and mechanical devices, common tools include screwdrivers, pliers, multimeters, oscilloscopes, 3D scanners, and CAD software. For software and firmware, common tools include disassemblers, debuggers, hex editors, and decompilers.

How long does it take to reverse engineer something?

The time required to reverse engineer something depends on the complexity of the item, the skills and experience of the engineer, and the tools and resources available. Simple devices or programs may only take a few hours or days to reverse engineer, while more complex systems can take weeks, months, or even years. Reverse engineering is often an iterative process, with multiple rounds of analysis, prototyping, and testing required to fully understand and replicate the item.

What skills are needed for reverse engineering?

Reverse engineering requires a diverse set of skills, depending on the type of item being analyzed. For consumer electronics and mechanical devices, important skills include electrical and mechanical engineering, materials science, and manufacturing processes. For software and firmware, important skills include programming, software architecture, and familiarity with low-level languages like assembly. In general, successful reverse engineering also requires strong problem-solving skills, attention to detail, and the ability to think creatively and analytically.

Can I reverse engineer something and sell the results?

The answer to this question depends on the specific item being reverse-engineered and the applicable laws and regulations. In some cases, reverse engineering and selling the results may be protected under fair use or other legal doctrines, especially if the results are used for interoperability or other legitimate purposes. However, in other cases, selling reverse-engineered products may be considered copyright or patent infringement, especially if the original item is protected by intellectual property laws. It’s important to carefully consider the legal implications of reverse engineering and consult with qualified legal professionals before attempting to sell any reverse-engineered products.