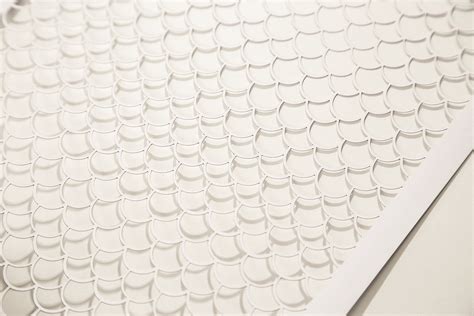

Laser Cut Framed Stencils

Introduction to Laser-Cut Stencils

Laser-cut stencils have revolutionized the world of art and crafting, offering a precise and efficient method for creating intricate designs on various surfaces. These stencils are made using laser cutting technology, which allows for highly detailed and accurate cuts in a wide range of materials, including paper, plastic, wood, and metal. The versatility and precision of laser-cut stencils have made them popular among artists, crafters, and DIY enthusiasts alike.

What Are Laser-Cut Stencils?

Laser-cut stencils are templates created using a laser cutting machine. The machine uses a high-powered laser beam to cut through the chosen material, following a pre-programmed design. The result is a stencil with clean, precise edges that can be used to transfer the design onto another surface using paint, spray, or other mediums.

Advantages of Laser-Cut Stencils

Compared to traditional hand-cut stencils, laser-cut stencils offer several advantages:

- Precision: Laser cutting technology allows for intricate and detailed designs with clean, sharp edges.

- Consistency: Laser-cut stencils ensure that the design is consistently reproduced each time the stencil is used.

- Durability: Depending on the material used, laser-cut stencils can be more durable and long-lasting than hand-cut stencils.

- Efficiency: Laser cutting machines can produce stencils quickly and accurately, saving time and effort compared to hand-cutting.

Types of Materials for Laser-Cut Stencils

Laser-cut stencils can be made from a variety of materials, each with its own unique properties and advantages. Some of the most common materials used for laser-cut stencils include:

Paper and Cardstock

Paper and cardstock are affordable and easily accessible materials for creating laser-cut stencils. They are suitable for single-use or short-term projects and can be used with various mediums, such as paint, spray, and ink.

Plastic

Plastic stencils are more durable and reusable compared to paper stencils. They are ideal for projects that require multiple applications of the same design. Some common plastic materials used for laser-cut stencils include:

- Mylar

- Acetate

- Polypropylene

Wood

Laser-cut wood stencils offer a unique, rustic appearance and are perfect for creating signs, wall art, and other decorative items. They can be used with paint, stain, or burn techniques to achieve various effects.

Metal

Metal stencils, such as stainless steel or brass, are extremely durable and long-lasting. They are suitable for industrial applications, such as marking and labeling, as well as for creating unique art pieces.

Designing Laser-Cut Stencils

Creating a design for a laser-cut stencil involves several steps and considerations. Here are some key aspects to keep in mind when designing your stencil:

Software and File Formats

To create a design for laser cutting, you’ll need to use vector-based software such as Adobe Illustrator, CorelDRAW, or Inkscape. These programs allow you to create scalable designs that can be easily adjusted and resized without losing quality. When saving your design, ensure that you use a compatible file format, such as AI, EPS, or SVG.

Design Considerations

When designing your laser-cut stencil, consider the following factors:

- Bridges and Islands: Ensure that your design has proper bridges (connections) between elements to prevent isolated islands (floating pieces) from falling out of the stencil.

- Line Thickness: Use appropriate line thicknesses to ensure that the laser cutter can accurately reproduce your design. Thin lines may not cut properly, while thick lines may result in a loss of detail.

- Negative Space: Remember that the negative space (the areas that will be cut out) in your design will be the parts that allow the medium to pass through and create the image on your surface.

Choosing a Laser Cutting Service

If you don’t have access to a laser cutter, you can use online laser cutting services to bring your stencil design to life. Some popular services include:

- Ponoko

- Sculpteo

- Shapeways

When choosing a service, consider factors such as material options, pricing, turnaround time, and shipping costs.

Framing Laser-Cut Stencils

Framing your laser-cut stencils can enhance their durability, make them easier to handle, and provide a more professional appearance. Here are some methods for framing your stencils:

Wooden Frames

Wooden frames are a classic choice for framing stencils. They offer a sturdy and attractive option that can be customized to suit your style. To create a wooden frame for your stencil:

- Measure your stencil and cut four pieces of wood to create a frame that’s slightly larger than the stencil.

- Use wood glue and nails or screws to assemble the frame.

- Sand the frame and apply a finish, such as paint or stain, if desired.

- Attach your stencil to the back of the frame using adhesive or small nails.

Acrylic Frames

Acrylic frames provide a sleek, modern look for your laser-cut stencils. They are lightweight, durable, and easy to clean. To frame your stencil with acrylic:

- Measure your stencil and cut two pieces of acrylic to size – one for the front and one for the back.

- Use clear adhesive or double-sided tape to attach your stencil to the back piece of acrylic.

- Place the front piece of acrylic over the stencil and secure the edges with clear adhesive or tape.

Magnetic Frames

Magnetic frames are a versatile option that allows you to easily swap out stencils as needed. To create a magnetic frame:

- Cut a sheet of metal to the desired size of your frame.

- Attach magnets to the back of your stencil using adhesive.

- Place the stencil on the metal sheet, where it will be held in place by the magnets.

Applications and Projects

Laser-cut stencils can be used for a wide range of applications and projects, from home decor to professional signage. Here are some ideas to inspire your creativity:

Wall Art

Create unique wall art by using your laser-cut stencils to paint or spray designs onto canvas, wood, or directly onto your walls. Experiment with different colors, patterns, and layering techniques to achieve stunning results.

Fabric and Textile Designs

Use your stencils to create custom designs on fabric for clothing, pillows, curtains, or other textile projects. You can use fabric paint, bleach, or dye to transfer your designs onto the material.

Signage and Labeling

Laser-cut stencils are perfect for creating professional-looking signage and labels for businesses, events, or personal use. Use your stencils to paint or etch designs onto wood, metal, or plastic surfaces.

Decorative Items

Incorporate laser-cut stencils into your DIY projects to create unique decorative items, such as:

- Coasters

- Bookends

- Trays

- Plaques

Packaging and Branding

Use laser-cut stencils to add custom branding or designs to product packaging, business cards, or promotional materials. This can help create a cohesive and professional look for your business or personal brand.

Frequently Asked Questions (FAQ)

-

Q: Can I create my own designs for laser-cut stencils?

A: Yes, you can create your own designs using vector-based software such as Adobe Illustrator, CorelDRAW, or Inkscape. Ensure that your design is compatible with laser cutting by following the appropriate guidelines for line thickness, bridges, and islands. -

Q: How long do laser-cut stencils last?

A: The durability of laser-cut stencils depends on the material used. Paper and cardstock stencils are suitable for single-use or short-term projects, while plastic, wood, and metal stencils can last for multiple uses and longer periods. -

Q: What is the best material for creating reusable laser-cut stencils?

A: Plastic materials, such as Mylar or acetate, are ideal for creating reusable laser-cut stencils. They are durable, flexible, and easy to clean, making them suitable for multiple applications. -

Q: Can I use laser-cut stencils on any surface?

A: Laser-cut stencils can be used on a variety of surfaces, including paper, fabric, wood, metal, and plastic. However, it’s essential to consider the compatibility of your chosen medium with the surface material to ensure the best results. -

Q: How do I clean my laser-cut stencils after use?

A: To clean your laser-cut stencils, rinse them with warm water and mild soap, then gently scrub away any remaining paint or medium with a soft brush. Rinse the stencils again and allow them to air dry completely before storing or reusing them.

Conclusion

Laser-cut stencils offer a precise, efficient, and versatile way to create stunning designs on a wide range of surfaces. By understanding the materials, design considerations, and framing options available, you can unleash your creativity and produce professional-looking results for your art, crafting, or DIY projects. Whether you’re creating wall art, fabric designs, signage, or decorative items, laser-cut stencils provide endless possibilities for customization and personalization. So, embrace the power of laser cutting technology and start bringing your unique designs to life today!