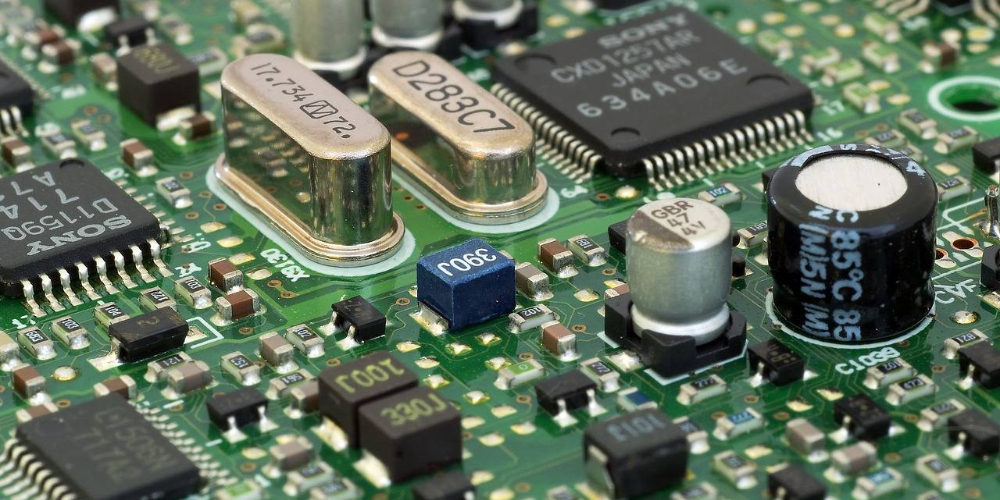

In the PCB copy process, we often need to disassemble the circuit board, remove the integrated circuit and other components to create a BOM list, and will be disassembled from the bare board to scan and copy the board. The integrated circuit pins are not only more dense, disassembly is often easy to make mistakes and thus damage the board, resulting in the failure of PCB copy. Therefore, in the process of PCB copy, how to correctly disassemble the integrated circuits on the PCB board becomes an important issue.

Shenzhen RayMing Technology’s senior team of professional PCB copy board companies said that PCB copy board is very much focused on technology and experience, especially in the disassembly of integrated circuits, but also the key to the successful implementation of PCB copy board. The following is Shenzhen RayMing summary of more than a decade of PCB copy board experience, now provides you with several easy and effective methods to disassemble the circuit board for your reference.

A. Solder sucker tin disassembly method

The use of solder absorbers to disassemble the integrated block, which is a common professional method, the use of tools for ordinary suction, soldering soldering iron, the power of more than 35W. When disassembling the integrated block, as long as the heated dual-use soldering iron head on the pins of the integrated block to be disassembled, to be melted solder joint tin is sucked into the fine tin ware, all the pins of the solder sucked after the integrated block can be taken off.

Second, medical hollow pin disassembly method

Take a few medical hollow pins of 8 to 12. When the use of the needle is just the right set of internal warp integration block pins appropriate. Disassembly with a soldering iron to dissolve the pin solder, in time to use the pin set pin, then remove the soldering iron and rotate the pin, and so the solder solidification after pulling out the pin. So the pin is completely separated from the printed board. After all the pins are done once, the integrated block can be easily taken off.

Three, multi-strand copper wire suction tin removal method

It is the use of multi-strand copper core plastic wire, remove the plastic skin, use multi-strand copper core wire (can use short wire head). Before using the multi-stranded copper core wire on the rosin alcohol solution, to be hot soldering iron will be multi-stranded copper core wire into the integrated block pins heated, so that the tin solder on the pins will be adsorbed by the copper wire, suck on the part of the solder can be cut off, repeated several times on the pins can be sucked away all the solder. Conditions can also use the braided wire inside the shield. As long as the solder sucked, with tweezers or a small “a” screwdriver gently pry, the integrated block can be removed.

Four, soldering iron brush with disassembly method

The method is simple and easy, as long as there is a soldering iron and a small brush can be. When disassembling the integrated block, the soldering iron is first heated to reach the melting temperature of the solder on the pins, and then take the opportunity to sweep off the melted solder with a brush. In this way, the pins of the integrated block can be separated from the printed board. The method can be divided into pins or can be carried out separately. Finally, use pointed tweezers or small “a” screwdriver to pry down the integrated block.

Five, increase the solder melting demolition method

The method is a hassle-free method, as long as the integrated block to be disassembled on the pins and then increase some solder, so that the solder joints of each column of pins are connected, so as to facilitate heat transfer, easy to disassemble. When disassembly with a soldering iron each heated column of pins with pointed tweezers or small “a” screwdriver pry a pry, two columns of pins rotating heating, until removed. In general, each column of pins heated twice can be removed.

Thus, although the PCB copy process of disassembling the integrated circuit is easy to make mistakes, but as long as the step-by-step, according to the correct method of disassembly, you can ensure the complete disassembly of the integrated circuit, the successful completion of the PCB copy board to lay a solid foundation.

Of course, in the PCB copy process, in addition to the disassembly of integrated circuits, there are many details that need attention. Shenzhen RayMing has a professional PCB copy team, which has accumulated rich experience in the process of copying boards for more than ten years, and is sincere in solving problems and providing more new strength for the steady development of PCB copy boards in China.