What are PCB Slots?

PCB slots are elongated openings or cutouts in a printed circuit board that serve specific purposes, such as:

- Accommodating connectors or other components

- Providing mechanical support for the board

- Facilitating board mounting in enclosures or chassis

- Improving airflow and heat dissipation

- Allowing for the passage of cables or wires

These slots come in various shapes and sizes, depending on their intended use and the requirements of the electronic device.

Types of PCB Slots

There are several types of PCB slots, each designed to fulfill specific functions:

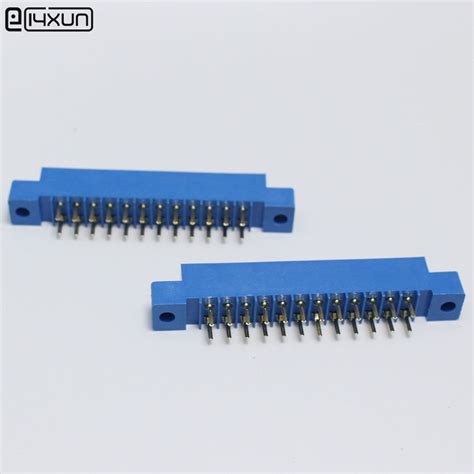

1. Edge Connector Slots

Edge connector slots are located at the edge of a PCB and are used to accommodate connectors that allow the board to interface with other devices or systems. These slots often have gold-plated fingers that make contact with the connector pins, ensuring reliable electrical connections.

2. Mounting Slots

Mounting slots are used to secure the PCB to an enclosure or chassis. These slots allow for the use of screws, standoffs, or other fasteners to hold the board in place, providing mechanical stability and preventing damage from vibration or shock.

3. Tooling Slots

Tooling slots, also known as fiducial slots, are small openings in the PCB that serve as reference points for automated assembly equipment. These slots help align the board correctly during the pick-and-place process, ensuring accurate component placement.

4. Ventilation Slots

Ventilation slots are designed to improve airflow and heat dissipation in electronic devices. By allowing air to circulate more freely around the components, these slots help prevent overheating and extend the lifespan of the electronic components.

5. Cable Slots

Cable slots are openings in the PCB that allow for the passage of cables or wires. These slots are particularly useful in devices that require internal wiring or when connecting multiple boards together.

PCB Slot Design Considerations

When designing PCB slots, several factors must be taken into account to ensure optimal functionality and manufacturability:

1. Slot Dimensions

The dimensions of a PCB slot should be carefully considered based on the specific requirements of the components or connectors it will accommodate. Designers must ensure that the slot is large enough to allow for easy insertion and removal of the component while maintaining a secure fit.

2. Slot Placement

The placement of slots on a PCB is critical for both functionality and manufacturability. Slots should be positioned in a way that allows for efficient routing of traces and the placement of components while avoiding potential manufacturing issues, such as drill breakout or weakening of the board structure.

3. Tolerances

PCB slot tolerances must be carefully specified to ensure proper fit and function. Designers should work closely with manufacturers to determine the appropriate tolerances based on the chosen fabrication process and materials.

4. Material Selection

The choice of PCB material can impact the design and performance of slots. Some materials, such as FR-4, are more prone to chipping or cracking during the slotting process, while others, like polyimide, offer better mechanical stability. Designers should consider the material properties when specifying slot dimensions and tolerances.

5. Manufacturing Processes

Different manufacturing processes can be used to create PCB slots, such as routing, punching, or laser cutting. Each process has its advantages and limitations, and designers should work with manufacturers to select the most appropriate method based on the slot requirements and production volume.

Benefits of Using PCB Slots

Incorporating slots into your PCB design offers several benefits:

1. Enhanced Connectivity

Edge connector slots allow for easy and reliable connection between the PCB and other devices or systems, enabling seamless data transfer and power supply.

2. Improved Mechanical Stability

Mounting slots provide a secure and stable means of attaching the PCB to an enclosure or chassis, reducing the risk of damage from vibration or physical stress.

3. Increased Reliability

Properly designed and manufactured PCB slots contribute to the overall reliability of the electronic device by ensuring secure connections, adequate ventilation, and protection from environmental factors.

4. Simplified Assembly

Tooling slots and well-placed component slots streamline the automated assembly process, reducing the risk of errors and improving production efficiency.

5. Better Thermal Management

Ventilation slots promote better airflow and heat dissipation, helping to prevent component overheating and extend the lifespan of the electronic device.

PCB Slot Materials

PCB slots can be created in various materials, depending on the specific requirements of the application. Some common materials used for PCB slots include:

| Material | Characteristics |

|---|---|

| FR-4 | Most common PCB material, cost-effective, prone to chipping |

| Polyimide | High mechanical stability, suitable for Flexible PCBs |

| Aluminum | Excellent thermal conductivity, ideal for heat dissipation |

| Copper | High electrical conductivity, often used for grounding slots |

| Stainless Steel | Strong and durable, suitable for high-stress applications |

Designing PCB Slots for Manufacturing

To ensure the successful fabrication of PCB slots, designers should follow best practices and work closely with manufacturers. Some key considerations include:

1. Specify Slot Dimensions Clearly

Provide detailed drawings or specifications that clearly indicate the dimensions, tolerances, and placement of each slot on the PCB.

2. Consider Manufacturing Limitations

Work with your manufacturer to understand the limitations of their fabrication processes and equipment, and design slots accordingly.

3. Provide Adequate Clearance

Ensure that there is sufficient clearance around slots for traces, components, and other features to avoid manufacturing issues and signal interference.

4. Use Appropriate File Formats

When submitting PCB designs for manufacturing, use industry-standard file formats, such as Gerber or ODB++, to ensure accurate and efficient communication with the manufacturer.

Frequently Asked Questions (FAQ)

-

What is the minimum size for a PCB slot?

The minimum size for a PCB slot depends on the manufacturing process and the capabilities of the fabrication equipment. Typically, slots as small as 0.5mm wide can be achieved with modern PCB manufacturing techniques. -

Can PCB slots be used for grounding purposes?

Yes, PCB slots can be used for grounding purposes. Copper-plated slots, known as grounding slots, provide a low-impedance path to ground, helping to reduce electromagnetic interference (EMI) and improve signal integrity. -

How do I choose the right material for my PCB slots?

The choice of material for PCB slots depends on the specific requirements of your application. Factors to consider include mechanical stability, thermal conductivity, electrical properties, and cost. Consult with your manufacturer to select the most suitable material for your project. -

Are there any limitations on the number of slots I can have on a PCB?

The number of slots on a PCB is limited by the available space and the overall design constraints. Too many slots can weaken the board structure and complicate the routing of traces. Designers should strive for a balance between functionality and manufacturability when incorporating slots into their PCB layouts. -

Can PCB slots be added after the board has been fabricated?

While it is possible to add slots to a PCB after fabrication using techniques like milling or drilling, it is generally not recommended. Adding slots post-fabrication can introduce mechanical stress, damage traces, and compromise the overall integrity of the board. It is best to incorporate slots into the initial PCB design whenever possible.

Conclusion

PCB slots are a vital aspect of electronics assembly, providing a range of functions that contribute to the performance, reliability, and manufacturability of electronic devices. By understanding the types of slots, their design considerations, and the benefits they offer, designers can create PCBs that are optimized for their specific applications.

When designing PCB slots, it is essential to consider factors such as dimensions, placement, tolerances, material selection, and manufacturing processes. By working closely with manufacturers and following best practices, designers can ensure that their PCB slots are fabricated accurately and efficiently, resulting in a high-quality final product.

As the electronics industry continues to evolve, the importance of well-designed PCB slots will only continue to grow. By staying informed about the latest technologies and techniques related to PCB slots, designers can create innovative and reliable electronic devices that meet the ever-changing demands of the market.