PCB Layout Design Service

Introduction to PCB Layout Design Printed Circuit Board (PCB) layout design is a crucial step in the development of electronic devices. It involves the arrangement of components an

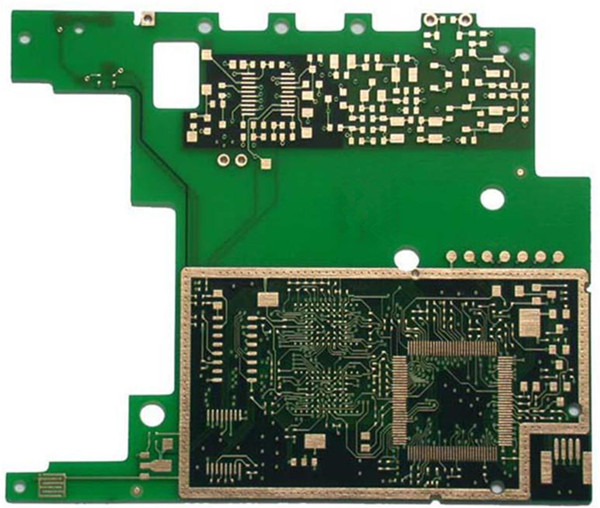

PCB REVERSE ENGINEERING

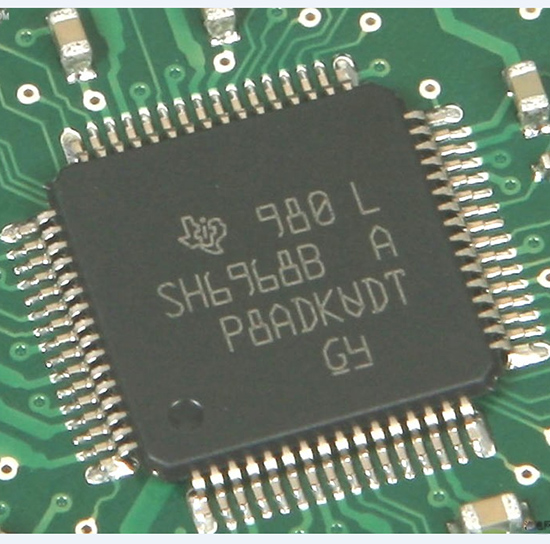

IC Unlock + PCB Reverse engineering Services - We will crack your IC sample. You will receive IC program in Bin / Hex file for burning any new ICs

PCB to schematic, Schematic to Gerber file, PCBA to Schematic Gerber & Bom List

We focus on a strategy of continuous customer-centric innovation. The goal is to deliver timely solutions for anticipated and actual customer.

We offer our customers from around the world to maintain a very good communication and product support services.

We will reverse engineer your PCB sample, and deilver the engineering file into:1. PCB 2. Gerber File 3. BOM List 4. Schematic Diagram

16 years deep in the reverse analysis of integrated circuit technology, senior technical team, skilled, experienced in a variety of blind buried hole PCB , laser blind hole board, UHF board, ceramic board , component density, all over the microstrip lines and other long lines, high-frequency processing requirements and strict control of electromagnetic compatibility of the communication board copy

All about PCB Reverse Engineering & IC Crack

Introduction to PCB Layout Design Printed Circuit Board (PCB) layout design is a crucial step in the development of electronic devices. It involves the arrangement of components an

Types of Finger Sensors There are several types of finger sensors, each with its own unique properties and applications. Let's take a closer look at some of the most common types:

What are PCB Slots? PCB slots are elongated openings or cutouts in a printed circuit board that serve specific purposes, such as: Accommodating connectors or other components Prov