Which software is used to program PIC microcontroller?

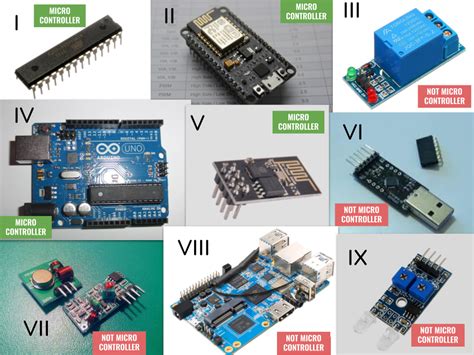

What is a PIC microcontroller?

Before we dive into the software options, let’s first understand what a PIC microcontroller is. PIC stands for “Peripheral Interface Controller” and refers to a family of microcontrollers developed by Microchip Technology. These microcontrollers are designed for embedded applications and offer a wide range of features such as:

- Low power consumption

- High performance

- Integrated peripherals (e.g. ADC, PWM, UART)

- In-circuit programming and debugging

PIC microcontrollers come in various sizes and configurations, ranging from 8-pin to 100-pin packages with different memory sizes and peripheral options. Some popular PIC microcontroller families include:

- PIC10

- PIC12

- PIC16

- PIC18

- PIC24

- dsPIC

PIC Programming software options

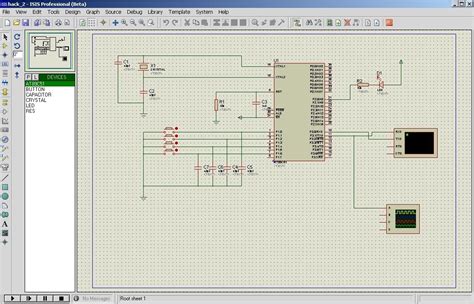

To program a PIC microcontroller, you need to use an Integrated Development Environment (IDE) that supports the specific device you are using. An IDE is a software application that provides a comprehensive environment for writing, compiling, and debugging code. Here are some of the most popular PIC programming software options:

MPLAB X IDE

MPLAB X IDE is the official IDE provided by Microchip for programming PIC microcontrollers. It is a free, cross-platform software that supports all PIC devices and offers a wide range of features such as:

- Syntax highlighting and code completion

- Integrated debugger and programmer

- Code profiling and optimization

- Plugin support for third-party tools

MPLAB X IDE uses the MPLAB XC compilers, which are available in both free and paid versions. The free version has some limitations in terms of optimization and code size, while the paid version offers full optimization and support.

To get started with MPLAB X IDE, you need to:

- Download and install MPLAB X IDE from the Microchip website

- Select your PIC device and compiler

- Write your code in C or assembly language

- Compile and debug your code using the integrated tools

- Upload your code to the PIC microcontroller using a programmer (e.g. PICkit, ICD)

MPLAB X IDE is a powerful and versatile tool for PIC programming, but it can have a steep learning curve for beginners.

MPLAB IPE

MPLAB IPE (Integrated Programming Environment) is a simplified version of MPLAB X IDE that focuses on programming and debugging PIC microcontrollers. It is a free, standalone application that supports most PIC devices and offers a user-friendly interface for quick programming tasks.

MPLAB IPE includes features such as:

- Simplified project creation and management

- Integrated programmer and debugger support

- Automatic device detection and configuration

- Firmware updates for programmers and debuggers

To use MPLAB IPE, you need to:

- Download and install MPLAB IPE from the Microchip website

- Connect your PIC microcontroller to the programmer or debugger

- Select your device and configure the programming settings

- Load your hex file and program the device

MPLAB IPE is a great choice for simple programming tasks or for beginners who want a more straightforward interface.

PICkit

PICkit is a series of low-cost programmers and debuggers for PIC microcontrollers. These tools are designed to work with MPLAB X IDE and MPLAB IPE and offer features such as:

- In-circuit programming and debugging

- Firmware updates for PIC microcontrollers

- Breakpoint and single-step debugging

- Real-time variable monitoring

The latest version of PICkit is PICkit 4, which supports most PIC devices and offers faster programming speeds and advanced debugging features. To use PICkit with MPLAB X IDE or MPLAB IPE, you need to:

- Connect PICkit to your computer and PIC microcontroller

- Select PICkit as your programmer or debugger in the IDE

- Configure the programming settings and load your code

- Program or debug your code using the integrated tools

PICkit is a cost-effective and reliable tool for PIC programming and debugging.

mikroC for PIC

mikroC for PIC is a commercial IDE developed by mikroElektronika for programming PIC microcontrollers. It is a powerful and user-friendly software that offers features such as:

- Simplified syntax and code examples

- Integrated debugger and programmer support

- Libraries and tools for common peripherals (e.g. LCD, EEPROM)

- Automatic code generation and optimization

mikroC for PIC uses a custom compiler that is optimized for PIC devices and offers faster compilation times and smaller code size compared to other compilers. However, it is a paid software and requires a license for commercial use.

To use mikroC for PIC, you need to:

- Download and install mikroC for PIC from the mikroElektronika website

- Select your PIC device and configure the project settings

- Write your code using the simplified syntax and libraries

- Compile and debug your code using the integrated tools

- Upload your code to the PIC microcontroller using a supported programmer

mikroC for PIC is a great choice for beginners who want a simplified and intuitive interface for PIC programming.

CCS PIC C Compiler

CCS PIC C Compiler is another commercial IDE for programming PIC microcontrollers using the C language. It is a powerful and feature-rich software that offers:

- ANSI C compiler with PIC-specific extensions

- Integrated debugger and programmer support

- Libraries and examples for common applications

- Automatic code generation and optimization

CCS PIC C Compiler is known for its efficient and optimized code generation, which can result in faster and smaller code compared to other compilers. However, it is a paid software and requires a license for commercial use.

To use CCS PIC C Compiler, you need to:

- Download and install CCS PIC C Compiler from the CCS website

- Select your PIC device and configure the project settings

- Write your code using the ANSI C syntax and PIC-specific extensions

- Compile and debug your code using the integrated tools

- Upload your code to the PIC microcontroller using a supported programmer

CCS PIC C Compiler is a great choice for experienced embedded programmers who want a powerful and efficient tool for PIC programming.

Comparison of PIC programming software

| Software | Vendor | License | Supported Devices | Features |

|---|---|---|---|---|

| MPLAB X IDE | Microchip | Free | All PIC devices | Syntax highlighting, integrated debugger, code optimization |

| MPLAB IPE | Microchip | Free | Most PIC devices | Simplified interface, automatic device detection |

| PICkit | Microchip | Paid | Most PIC devices | In-circuit programming and debugging, firmware updates |

| mikroC for PIC | mikroElektronika | Paid | Most PIC devices | Simplified syntax, integrated debugger, libraries and tools |

| CCS PIC C Compiler | CCS | Paid | Most PIC devices | ANSI C compiler, integrated debugger, efficient code generation |

Choosing the right PIC programming software depends on your specific needs and preferences. If you are a beginner, you may prefer a simplified interface like MPLAB IPE or mikroC for PIC. If you are an experienced programmer, you may prefer a more powerful and feature-rich IDE like MPLAB X IDE or CCS PIC C Compiler. Ultimately, the best software is the one that allows you to write, compile, and debug your code efficiently and effectively.

FAQ

What is the best PIC programming software for beginners?

For beginners, MPLAB IPE or mikroC for PIC are good choices due to their simplified interfaces and easy-to-use features. MPLAB IPE is a free software provided by Microchip, while mikroC for PIC is a paid software with a more intuitive syntax and built-in libraries.

Can I use Arduino IDE to program PIC microcontrollers?

No, Arduino IDE is designed specifically for Arduino boards and does not support PIC microcontrollers. To program PIC microcontrollers, you need to use a specialized IDE like MPLAB X IDE, MPLAB IPE, mikroC for PIC, or CCS PIC C Compiler.

Do I need a programmer to upload code to a PIC microcontroller?

Yes, you need a programmer or debugger to upload code to a PIC microcontroller. Some popular programmers include PICkit, ICD, and SNAP. These programmers connect to your computer via USB and allow you to transfer your code to the PIC device.

Can I use C++ to program PIC microcontrollers?

While most PIC programming software supports C language, some also support C++ with limitations. For example, MPLAB XC compilers support a subset of C++ features, while mikroC for PIC supports C++ with some modifications. However, using C++ for PIC programming may result in larger code size and slower performance compared to using C.

How do I choose the right PIC microcontroller for my project?

Choosing the right PIC microcontroller depends on your project requirements such as:

- Number of I/O pins

- Memory size

- Processing speed

- Peripheral options

- Power consumption

You can use Microchip’s product selector tool or consult with their technical support to find the best PIC device for your needs. It’s also important to consider the availability and cost of the device, as well as the compatibility with your preferred programming software.

Conclusion

In this article, we explored the various software options available for PIC programming, including MPLAB X IDE, MPLAB IPE, PICkit, mikroC for PIC, and CCS PIC C Compiler. We also compared the features and benefits of each software and provided guidance on how to choose the right one for your needs.

PIC microcontrollers are a versatile and powerful platform for embedded systems and electronic projects. By using the right programming software and tools, you can unleash the full potential of these devices and create innovative solutions for a wide range of applications.

Whether you are a beginner or an experienced programmer, there is a PIC programming software that can meet your needs and help you bring your ideas to life. So, choose your software wisely, write your code carefully, and happy programming!