What is PCB in aircraft?

Introduction

Printed Circuit Boards (PCBs) are an essential component in modern aircraft, enabling the complex electronic systems that power everything from navigation and communication to engine control and in-flight entertainment. In this comprehensive guide, we’ll explore the role of PCBs in aviation, their design and manufacturing process, and the unique challenges and regulations associated with their use in aircraft.

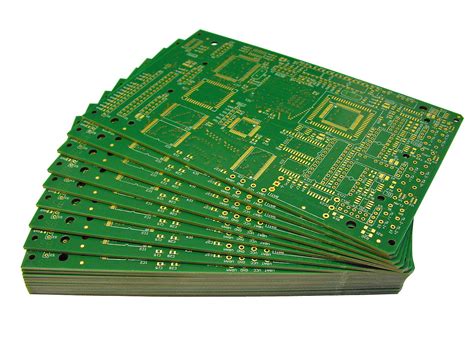

What are Printed Circuit Boards?

Definition and Components

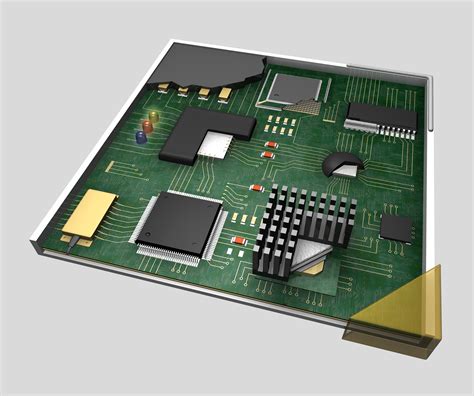

A Printed Circuit Board (PCB) is a thin board made of insulating material, such as fiberglass or composite, with conductive copper traces etched onto its surface. These traces connect various electronic components, such as resistors, capacitors, and integrated circuits (ICs), to form a complete electronic circuit.

The main components of a PCB include:

- Substrate: The insulating board that provides mechanical support and electrical insulation

- Copper traces: Conductive pathways that connect components

- Solder mask: A protective layer that prevents short circuits and corrosion

- Silkscreen: Text and symbols printed on the board for identification and assembly

- Electronic components: The various parts that make up the circuit, such as resistors, capacitors, and ICs

Types of PCBs

PCBs can be classified based on the number of conductive layers they contain:

- Single-sided PCBs: These have copper traces on only one side of the substrate and are suitable for simple, low-density circuits.

- Double-sided PCBs: With copper traces on both sides of the substrate, these boards offer higher component density and more complex routing options.

- Multi-layer PCBs: These consist of multiple layers of conductive traces separated by insulating layers, allowing for even higher component density and more complex circuits. Multi-layer PCBs are commonly used in aircraft electronics.

The Role of PCBs in Aircraft

Avionics and Flight Control Systems

PCBs are the backbone of an aircraft’s avionics and flight control systems, which include:

- Navigation systems: GPS, INS, and radio navigation

- Communication systems: Radios, transponders, and data links

- Autopilot and flight management systems

- Instrument displays and control panels

These systems rely on high-performance PCBs to process data, communicate with other systems, and provide reliable operation in the demanding environment of an aircraft.

Engine Control and Monitoring

Modern aircraft engines are controlled and monitored by Electronic Engine Control (EEC) systems, which use PCBs to:

- Regulate fuel flow and ignition timing

- Monitor engine parameters such as temperature, pressure, and vibration

- Communicate with other aircraft systems and ground-based maintenance computers

The PCBs in these systems must be designed to withstand the high temperatures, vibrations, and electromagnetic interference (EMI) present in an aircraft engine environment.

In-Flight Entertainment and Cabin Systems

PCBs also play a crucial role in an aircraft’s passenger cabin, powering systems such as:

- In-flight entertainment (IFE) systems: Displays, audio systems, and content servers

- Cabin lighting and environmental control systems

- Passenger service units (PSUs) and call buttons

- Seat electronics, including power outlets and USB ports

These systems require PCBs that are lightweight, compact, and reliable, with the ability to interface with a variety of peripheral devices and networks.

PCB design and Manufacturing for Aircraft

Design Considerations

Designing PCBs for use in aircraft presents several unique challenges, including:

- Environmental factors: PCBs must be able to withstand extreme temperatures, humidity, vibration, and altitude changes.

- EMI and EMC: Aircraft electronics must not interfere with each other or with external systems, requiring careful design for electromagnetic compatibility (EMC).

- Size and weight constraints: PCBs must be as small and lightweight as possible to minimize their impact on aircraft performance and fuel efficiency.

- Reliability and redundancy: Aircraft systems require high levels of reliability and often incorporate redundant components and circuits to ensure continuous operation.

To address these challenges, PCB designers use specialized software tools and follow industry standards and guidelines, such as RTCA DO-160 and ARINC 600.

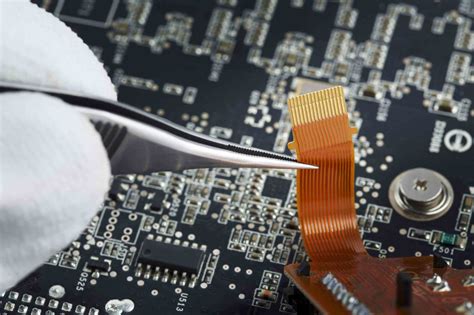

Manufacturing Process

The manufacturing process for aircraft PCBs involves several key steps:

- PCB design: The circuit is designed using CAD software, and the layout is optimized for manufacturability and performance.

- Fabrication: The bare PCB is manufactured using a multi-step process that includes:

- Creating the substrate

- Applying and patterning the copper layers

- Drilling holes and vias

- Applying solder mask and silkscreen

- Assembly: Electronic components are mounted onto the PCB using automated pick-and-place machines and soldered in place using reflow ovens or wave soldering.

- Testing and inspection: The assembled PCB undergoes rigorous testing and inspection to ensure it meets the required specifications and quality standards.

Throughout the manufacturing process, strict quality control measures are in place to ensure the PCBs meet the high reliability and performance requirements of the aviation industry.

Quality and Reliability Standards

PCBs used in aircraft must meet stringent quality and reliability standards to ensure the safety and performance of the aircraft. Some of the key standards and certifications include:

- RTCA DO-254: Design Assurance Guidance for Airborne Electronic Hardware

- RTCA DO-160: Environmental Conditions and Test Procedures for Airborne Equipment

- ARINC 600: Air Transport Avionics Equipment Interfaces

- AS9100: Quality Management Systems – Requirements for Aviation, Space, and Defense Organizations

Manufacturers of aircraft PCBs must demonstrate compliance with these standards through rigorous testing, documentation, and auditing processes.

Challenges and Future Trends

Environmental and Regulatory Challenges

The use of PCBs in aircraft presents several environmental and regulatory challenges, including:

- Hazardous materials: Some PCB manufacturing processes involve hazardous chemicals, such as lead and halogenated flame retardants, which are subject to increasingly strict regulations.

- Waste management: The disposal of end-of-life PCBs and electronic waste is a growing concern, requiring responsible recycling and waste management practices.

- Greenhouse gas emissions: The energy-intensive manufacturing process and the use of certain materials can contribute to greenhouse gas emissions, prompting the industry to explore more sustainable practices.

To address these challenges, the aviation industry is working to develop and adopt more environmentally friendly materials and processes, such as lead-free solders and halogen-free flame retardants.

Emerging Technologies and Trends

The future of PCBs in aircraft is shaped by several emerging technologies and trends, including:

- Additive manufacturing: 3D printing techniques, such as inkjet and aerosol jet printing, offer new possibilities for creating complex, lightweight PCBs with embedded components.

- Flexible and stretchable electronics: The development of flexible and stretchable PCB materials and components enables the integration of electronics into non-traditional aircraft structures, such as wings and fuselages.

- Wireless technologies: The increasing use of wireless communication and power transfer technologies, such as Bluetooth and inductive coupling, may reduce the need for physical PCB Connections in some applications.

- Modular and reconfigurable systems: The trend towards modular and reconfigurable aircraft systems may lead to the development of more standardized and interchangeable PCBs, facilitating maintenance and upgrades.

As these technologies mature, they are likely to have a significant impact on the design, manufacturing, and performance of PCBs in aircraft.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between a PCB and a circuit board?

A: “PCB” and “circuit board” are often used interchangeably, as a PCB is a type of circuit board. However, “circuit board” can also refer to other types of boards, such as breadboards or stripboards, which are used for prototyping or low-volume production. -

Q: Why are multi-layer PCBs commonly used in aircraft?

A: Multi-layer PCBs are used in aircraft because they offer several advantages, including higher component density, more complex routing options, and better EMI/EMC performance. These features are essential for the compact, high-performance electronic systems found in modern aircraft. -

Q: How do aircraft PCBs differ from those used in other industries?

A: Aircraft PCBs are designed and manufactured to meet the unique challenges of the aviation environment, such as extreme temperatures, vibration, and altitude changes. They also must comply with strict quality and reliability standards specific to the aerospace industry, such as RTCA DO-160 and ARINC 600. -

Q: What materials are used to make PCBs for aircraft?

A: PCBs for aircraft are typically made from high-performance materials, such as polyimide, PTFE, or high-temperature epoxy laminates. These materials offer excellent thermal stability, mechanical strength, and chemical resistance, making them suitable for the demanding conditions found in aircraft. -

Q: How are PCBs in aircraft tested to ensure reliability?

A: PCBs used in aircraft undergo rigorous testing to ensure they meet the required quality and reliability standards. This includes environmental testing (e.g., temperature, humidity, and vibration), EMI/EMC testing, and functional testing. Additionally, manufacturers must follow strict quality control processes and maintain detailed documentation to demonstrate compliance with industry standards.

Conclusion

Printed Circuit Boards play a critical role in enabling the complex electronic systems that power modern aircraft. From avionics and flight control to engine management and in-flight entertainment, PCBs are essential for ensuring the safety, efficiency, and comfort of air travel.

Designing and manufacturing PCBs for aircraft presents unique challenges, requiring specialized materials, processes, and quality standards to meet the demanding requirements of the aviation industry. As new technologies and trends emerge, the role of PCBs in aircraft will continue to evolve, driving innovation and shaping the future of aviation electronics.

By understanding the importance of PCBs in aircraft and the challenges associated with their design and manufacture, we can appreciate the vital role they play in keeping our skies safe and our aircraft at the forefront of technological advancement.