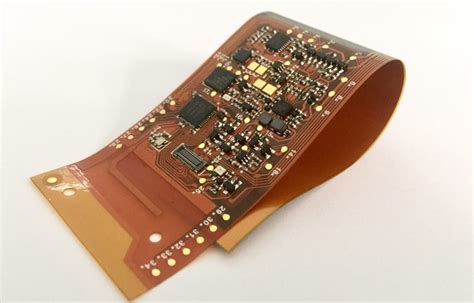

Introduction to Rigid-flex PCBs

Rigid-flex PCBs are a unique type of printed circuit board that combines the benefits of both rigid and flexible PCBs. They consist of rigid PCB sections connected by flexible PCB sections, allowing for three-dimensional packaging and improved reliability in applications that require flexibility or space savings.

Rigid-flex PCBs offer several advantages over traditional PCBs:

- Reduced weight and size

- Improved reliability and durability

- Enhanced electrical performance

- Increased design flexibility

- Simplified assembly process

As the demand for smaller, more complex electronic devices grows, rigid-flex PCBs are becoming increasingly popular in various industries, including:

- Aerospace and defense

- Medical devices

- Automotive electronics

- Consumer electronics

- Industrial automation

The Importance of Choosing the Right Rigid-flex PCB Manufacturer

Selecting the right rigid-flex PCB manufacturer is crucial to ensuring the success of your project. A reliable manufacturer will have the expertise, equipment, and quality control processes in place to produce high-quality rigid-flex PCBs that meet your specific requirements.

Choosing the wrong manufacturer can lead to several issues, such as:

- Inferior product quality

- Delays in production and delivery

- Increased costs due to rework or replacements

- Compliance issues with industry standards and regulations

- Damage to your company’s reputation

To avoid these problems and ensure the success of your project, it’s essential to carefully evaluate potential rigid-flex PCB manufacturers and select the one that best meets your needs.

Tip 1: Evaluate the Manufacturer’s Experience and Expertise

When choosing a rigid-flex PCB manufacturer, it’s important to consider their experience and expertise in producing rigid-flex PCBs. Look for a manufacturer with a proven track record of successfully delivering high-quality rigid-flex PCBs for projects similar to yours.

Some factors to consider when evaluating a manufacturer’s experience and expertise include:

- Years in the industry

- Types of rigid-flex PCBs produced

- Industries served

- Certifications and qualifications

- Customer testimonials and case studies

An experienced manufacturer will have the knowledge and skills necessary to navigate the unique challenges of rigid-flex PCB design and manufacturing, ensuring that your project is completed efficiently and to your specifications.

Tip 2: Assess the Manufacturer’s Quality Control Processes

Quality control is essential in rigid-flex PCB manufacturing to ensure that the final product meets your requirements and functions as intended. When evaluating potential manufacturers, inquire about their quality control processes and procedures.

A reputable rigid-flex PCB manufacturer should have:

- Documented quality management system (QMS)

- Adherence to industry standards (e.g., IPC, ISO, AS9100)

- Incoming material inspection and verification

- In-process quality checks and testing

- Final inspection and functional testing

- Traceability and record-keeping

By choosing a manufacturer with robust quality control processes, you can minimize the risk of receiving defective or substandard rigid-flex PCBs that could jeopardize your project’s success.

Tip 3: Consider the Manufacturer’s Capacity and Lead Times

When selecting a rigid-flex PCB manufacturer, it’s crucial to ensure that they have the capacity to meet your production needs and can deliver your order within the required lead times.

Factors to consider when assessing a manufacturer’s capacity and lead times include:

- Manufacturing facility size and equipment

- Production volume capabilities

- Typical lead times for rigid-flex PCBs

- Ability to accommodate rush orders or varying demand

- Inventory management and supply chain stability

Choosing a manufacturer with sufficient capacity and reliable lead times will help prevent delays in your project timeline and ensure that you receive your rigid-flex PCBs when you need them.

Tip 4: Evaluate the Manufacturer’s Design Support Capabilities

Rigid-flex PCB design can be complex, and having access to expert design support from your manufacturer can be invaluable in ensuring the success of your project. Look for a manufacturer that offers comprehensive design support services, such as:

- Design for manufacturability (DFM) analysis

- Signal integrity analysis

- Thermal analysis

- 3D modeling and simulation

- Prototyping and testing

A manufacturer with strong design support capabilities can help optimize your rigid-flex PCB design, identify and resolve potential issues early in the process, and ensure that your design is ready for production.

Tip 5: Consider the Manufacturer’s Technical Support and Customer Service

In addition to design support, it’s important to choose a rigid-flex PCB manufacturer that offers reliable technical support and customer service throughout the production process and beyond.

Look for a manufacturer that provides:

- Dedicated project management

- Regular communication and progress updates

- Timely responses to technical inquiries

- Post-delivery support and warranty

- Flexibility in accommodating changes or special requests

A manufacturer with strong technical support and customer service will be a valuable partner in ensuring the success of your rigid-flex PCB project.

Tip 6: Evaluate the Manufacturer’s Manufacturing Capabilities

Rigid-flex PCB manufacturing requires specialized equipment and processes to produce high-quality boards reliably. When choosing a manufacturer, evaluate their manufacturing capabilities to ensure they can meet your specific requirements.

Key manufacturing capabilities to consider include:

- Layer count and board thickness

- Material selection and compatibility

- Minimum feature sizes (e.g., line width, spacing, hole size)

- Surface finishes and soldermasks

- Controlled impedance

- Flex circuit coverlay materials and adhesives

A manufacturer with advanced manufacturing capabilities will be better equipped to produce complex rigid-flex PCBs that meet your design specifications and performance requirements.

Tip 7: Consider the Manufacturer’s Environmental Compliance and Sustainability

As environmental regulations become more stringent and consumers demand more eco-friendly products, it’s important to choose a rigid-flex PCB manufacturer that prioritizes environmental compliance and sustainability.

Look for a manufacturer that:

- Complies with environmental regulations (e.g., RoHS, REACH, WEEE)

- Implements sustainable manufacturing practices

- Uses eco-friendly materials and processes

- Has a documented environmental management system (EMS)

- Demonstrates a commitment to reducing waste and energy consumption

By selecting an environmentally responsible rigid-flex PCB manufacturer, you can ensure that your products meet regulatory requirements and appeal to environmentally conscious customers.

Tip 8: Evaluate the Manufacturer’s Pricing and Value

While price is an important consideration when choosing a rigid-flex PCB manufacturer, it’s essential to evaluate the overall value they provide rather than focusing solely on the lowest price.

Factors to consider when evaluating pricing and value include:

- Cost per unit and volume discounts

- Setup and tooling costs

- Minimum order quantities (MOQs)

- Shipping and logistics costs

- Value-added services (e.g., design support, testing, assembly)

A manufacturer that offers competitive pricing along with high-quality products, reliable service, and comprehensive support will provide the best overall value for your rigid-flex PCB project.

Tip 9: Verify the Manufacturer’s References and Reputation

Before making a final decision, it’s essential to verify the references and reputation of the rigid-flex PCB manufacturers you are considering. This will help you gauge their reliability, quality, and customer satisfaction.

Steps to verify a manufacturer’s references and reputation include:

- Request and contact customer references

- Review online reviews and ratings

- Check for any complaints or legal issues

- Verify certifications and compliance with industry standards

- Visit the manufacturer’s facility, if possible

By thoroughly vetting potential manufacturers, you can make an informed decision and choose a partner that will help ensure the success of your rigid-flex PCB project.

Conclusion

Choosing the right rigid-flex PCB manufacturer is critical to the success of your project. By following these nine tips and carefully evaluating potential manufacturers based on their experience, expertise, quality control, capacity, design support, technical support, manufacturing capabilities, environmental compliance, pricing, and reputation, you can select a reliable partner that will help bring your rigid-flex PCB design to life.

Investing time and effort in the selection process will pay off in the form of high-quality rigid-flex PCBs that meet your requirements, are delivered on time, and perform as intended. With the right manufacturer by your side, you can confidently navigate the complexities of rigid-flex PCB design and manufacturing and bring your innovative products to market successfully.

FAQ

1. What are the benefits of using rigid-flex PCBs?

Rigid-flex PCBs offer several benefits, including reduced weight and size, improved reliability and durability, enhanced electrical performance, increased design flexibility, and simplified assembly processes.

2. How do I determine if a rigid-flex PCB manufacturer has the necessary experience and expertise?

To evaluate a manufacturer’s experience and expertise, consider factors such as their years in the industry, types of rigid-flex PCBs produced, industries served, certifications and qualifications, and customer testimonials or case studies.

3. What should I look for in a manufacturer’s quality control processes?

A reputable rigid-flex PCB manufacturer should have a documented quality management system, adhere to industry standards, conduct incoming material inspections, perform in-process quality checks and testing, carry out final inspections and functional testing, and maintain traceability and record-keeping.

4. How can I ensure that a manufacturer can meet my production needs and lead times?

To assess a manufacturer’s capacity and lead times, consider factors such as their manufacturing facility size and equipment, production volume capabilities, typical lead times for rigid-flex PCBs, ability to accommodate rush orders or varying demand, and inventory management and supply chain stability.

5. What environmental compliance and sustainability factors should I consider when choosing a rigid-flex PCB manufacturer?

Look for a manufacturer that complies with environmental regulations (e.g., RoHS, REACH, WEEE), implements sustainable manufacturing practices, uses eco-friendly materials and processes, has a documented environmental management system, and demonstrates a commitment to reducing waste and energy consumption.