FPC SMD processing process: pretreatment → fixed → printing → SMD → reflow → test → inspection → sub-board.

FPC SMD processing need to provide information: 1. complete FPC do board file (Gerber file, placement chart, stencil file) and do board requirements; 2. complete BOM (including model, brand, package, description, etc.); 3. PCBA assembly diagram. ps: report PCBA function test cost, need to provide PCBA function test method.

FPC SMD processing notes:

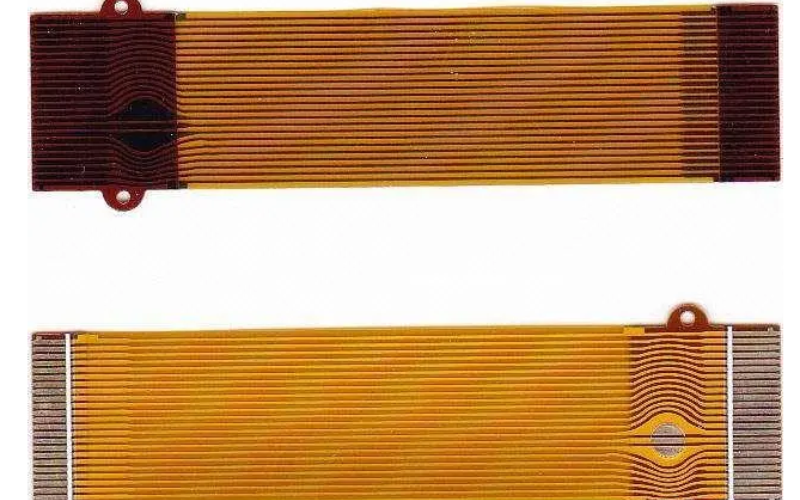

FPC fixed: from printing SMD to reflow soldering throughout the fixed on the pallet, the pallet used requires a small coefficient of thermal expansion.

solder paste printing: because the pallet is loaded with FPC, FPC with high-temperature tape for positioning, so that the height is not consistent with the pallet plane, so the printing must choose the elastic scraper, solder paste composition has a greater impact on the printing effect, you must choose the right solder paste.

mounting equipment: first, the best solder paste printing machine with optical positioning system, otherwise the quality of welding will have a greater impact. Secondly, the FPC is fixed on the pallet, but there will always be some tiny gap between the FPC and the pallet, which is a big difference with the PCB substrate. Therefore the equipment parameter setting will have a big influence on the printing effect, the placement accuracy and the welding effect.

Shenzhen RayMing technology is a professional FPC flexible circuit board SMT processing company, with more than ten years of experience in FPC flexible board SMD processing of a team of senior engineers, the industry’s first-class professional standard SMT factory management, professional to undertake FPC SMD processing business.