PCB will generally use which kind of terminal blocks which depends on whether it is according to the material to divide or style to divide, if according to the material, should be more copper terminal blocks; according to the style to divide, PCB terminals are divided into plug-in terminal blocks, direct welding terminal blocks, spring-type terminal blocks, fence type terminal blocks, should be plug-in terminal blocks and spring-type terminal blocks more.

Spring-type terminal block is the use of spring device of the new terminal block, has been widely used in the world of electrical and electronic engineering industry: lighting, elevator lift control, instrumentation, power, chemical and automotive power. Spring type series terminal block metal parts are spring device design, plastic body are used PA66 insulation material. Spring-type series terminal blocks are easy to operate, free maintenance and with gas-tight contact device system, that is durable and reliable and cost-effective.

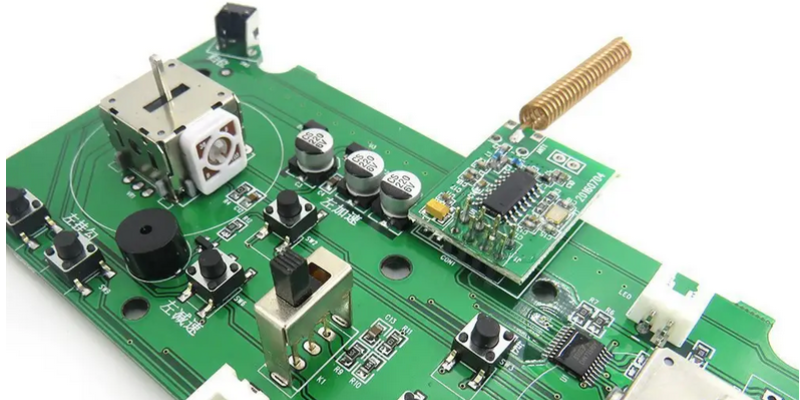

Plug-in series terminal blocks PTB by two parts plug-in connection, part of the line will be pressed, and then inserted into the other part, which is soldered to the PCB board. This connection bottom mechanical principle, this anti-vibration design to ensure the long-term airtight connection of the product and the reliability of the use of the finished product. The assembly lugs can be added to both ends of the socket, which largely protect the tabs and prevent poor alignment of the tabs, while the socket design ensures that the socket can be inserted correctly into the female body. The sockets can also have assembly and locking fasteners. The assembly fasteners provide a more secure attachment to the PCB board, while the locking fasteners lock the female and the socket after installation. A variety of socket designs are available with different insertion methods for the masters, such as horizontal, vertical or angled towards the PCB, depending on the customer’s requirements. Both metric and standard wire gauges can be selected.