It is understood that in recent years, due to the industrial robots with its can be a long time to repeat operations, in dangerous, harsh environments and other advantages, so that the government and the industry more and more attention to the robotics industry. Although China is a large country of labor, but with the demographic dividend inflection point, the rising cost of manpower, industrial robots will continue to expand the prospects for the use of space. Although the difficulties of independent research and development of industrial robots, but the dawn of hope is still flashing out, because some of the national consciousness, know how to use PCB copy board innovation and upgrading of the domestic reverse engineering enterprises such as RayMing Technology Co., Ltd. has successfully overcome the reducer of the robot’s key core components, and greatly accelerated the process of domestication of industrial robots.

The gap between domestic industrial robots and measures to make up for it

According to RayMing technology copy board experts analysis, caused by China’s industrial robot market profits are low and difficult to realize the localization of the reasons, on the one hand, China’s robotics research started late, although China’s research institutions are catching up, but the overall gap between the advanced level and foreign countries and one or two decades; on the other hand, the reducer of the robot joints, the key components can not be localized, and generally rely on the import. imported. If our country can digest and absorb foreign advanced technology through PCB copy board, and their own secondary innovation research and development manufacturing robot body precision devices, will greatly accelerate the process of robot research and development, shorten the gap with foreign countries, to achieve rapid industrial upgrading.

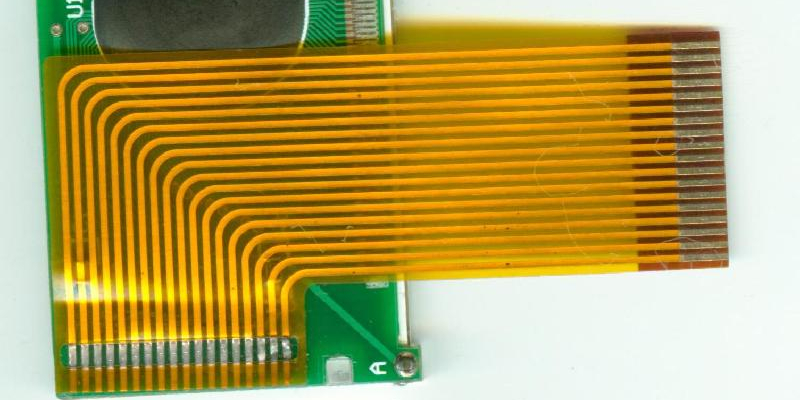

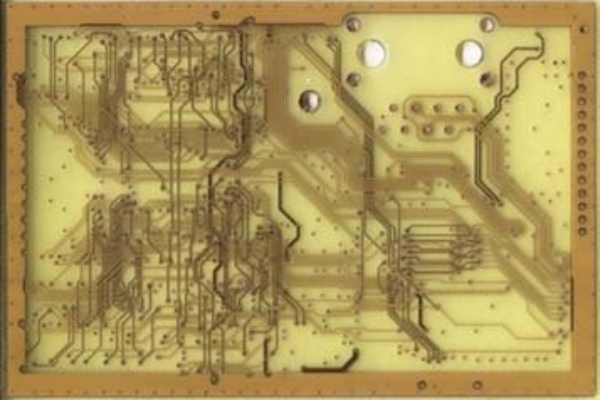

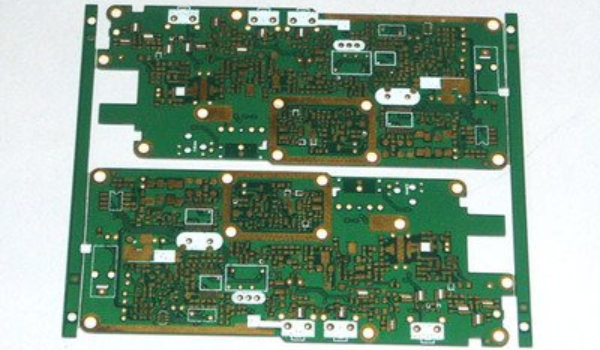

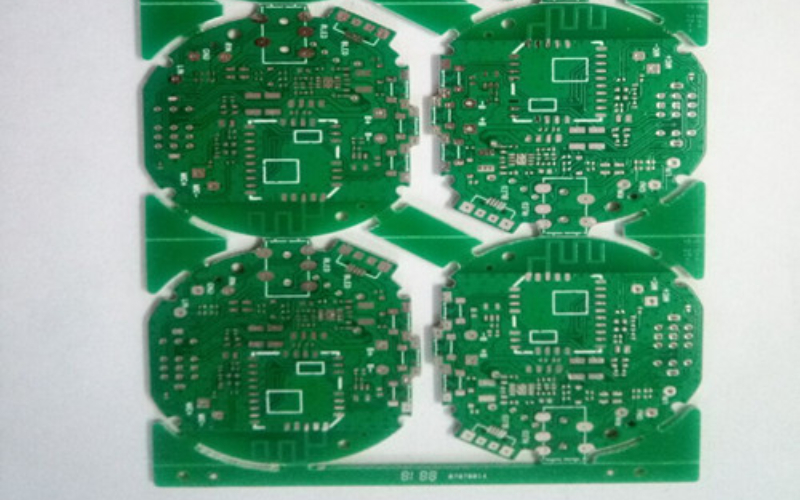

PCB copy board related concepts and innovative applications

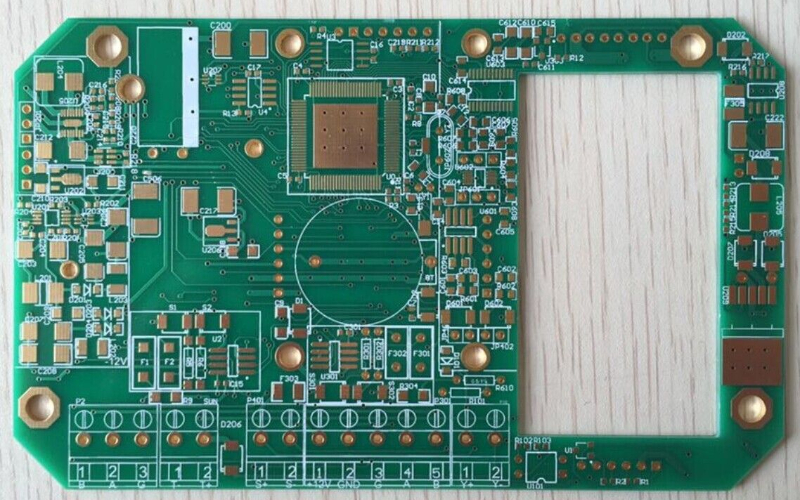

PCB copy board, that is, circuit board copy board, it is an advanced means of reverse research, through professional technical equipment and personnel, can be a complete copy of the circuit board design of foreign electronic products, and therefore can be short-term mastery of foreign core technology. Not only that, the circuit board copy board can also carry out the secondary development of hardware and software functions, according to the customer needs PCB change board, product customization and development, modify the parameters, colors and functions of the product, and quickly realize the development of new products. This technology was introduced into the country, was quickly applied, has helped countless small and medium-sized enterprises to realize the technological leap.

PCB copy board for the localization development of reducer

The same road, for the current domestic precision reducer is still in the sample test period, there has not been a large-scale industrial applications, and imports of whole industrial robots will weaken the status quo of domestic demand. China can first introduce a small number of high-end reducer PCB copy board reverse research, master its material selection, configuration design, sample testing and other basic knowledge, and then digested and absorbed after the continuous cycle of optimization, to make important product upgrades, and with the customer to find the positioning of the local market, localization development.

Of course, copy board technology is also a need to accumulate experience in the industry, not who want to do can do, without enough technical accumulation inevitably limited by the eye, it is easy to go into the wrong area of poor quality cottage. RayMing Technology, as a domestic veteran PCB copy board enterprise, has decades of rich experience in medical electronics, industrial control equipment, communications equipment, radio and television equipment, military equipment, automotive electronics, Household electronics and other industries have successfully launched countless innovative products. In recent years, the localization of imported equipment has also achieved a lot of results, and the successful copy board of the speed reducer is just one of the examples.RayMing Technology’s spirit of overcoming foreign technical barriers and secondary innovation will lay a solid technical foundation for the large-scale popularization of industrial robots, and bring a broad prospect for the further development of the national speed reducer manufacturing industry.