Why should I choose RayMing Technology for board copy?

With the rapid development of the copy board industry, there are many professional copy board enterprises in the market in recent years. Among these many copy board production enterprises, one company stands out with its professional quality and exquisite service – Shenzhen RayMing Technology Co.

RayMing Technology is the leader of the board copying industry, and the most lacking thing in the 21st century is innovative talents and enterprises. All industries are striving for survival in innovation, and only continuous innovation can make enterprises invincible and survive in the cruel market competition.

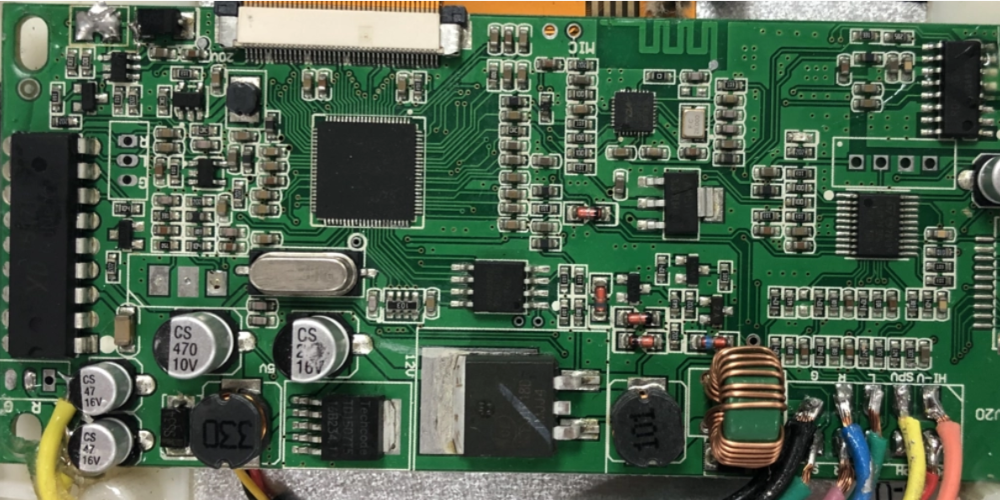

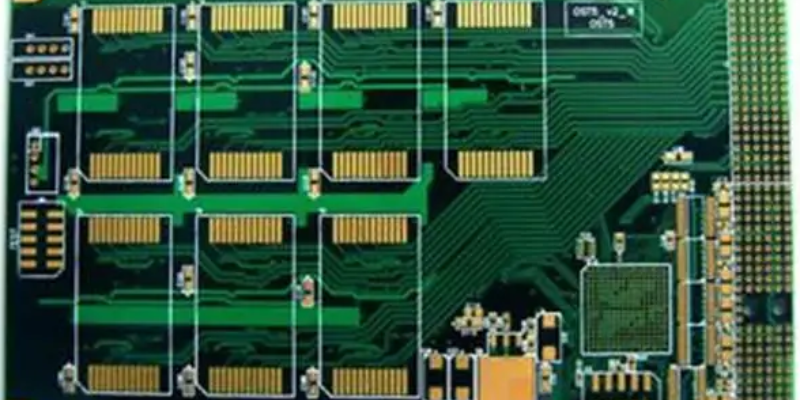

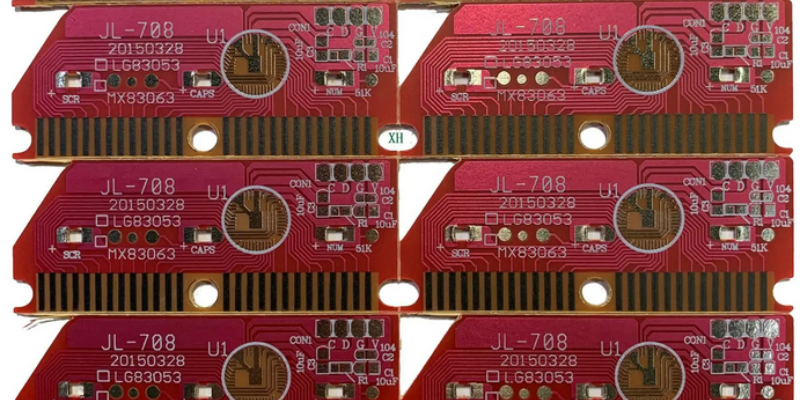

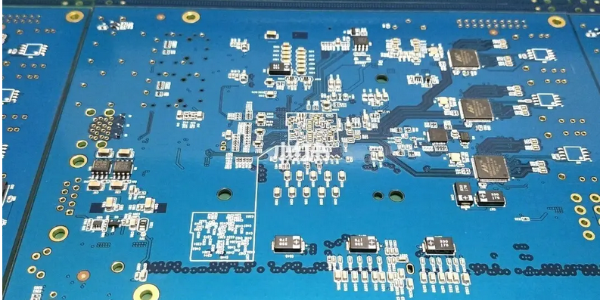

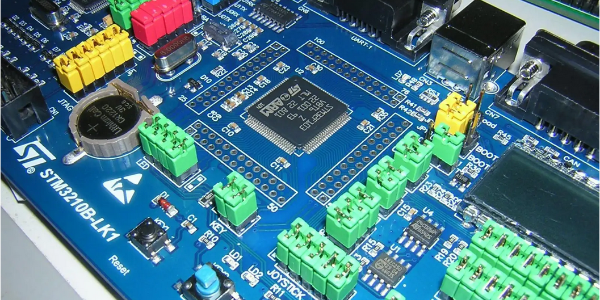

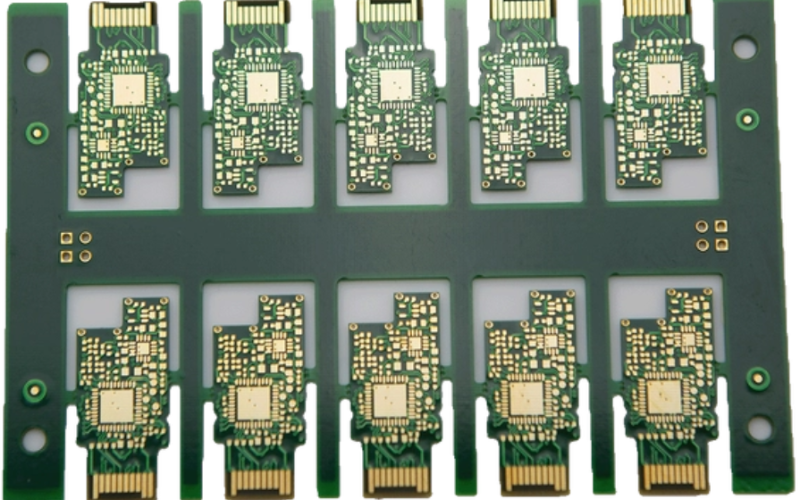

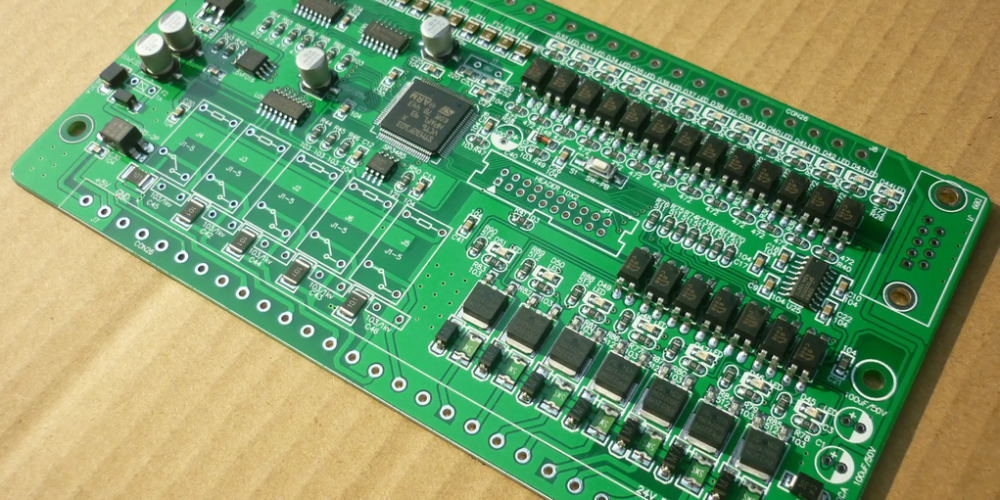

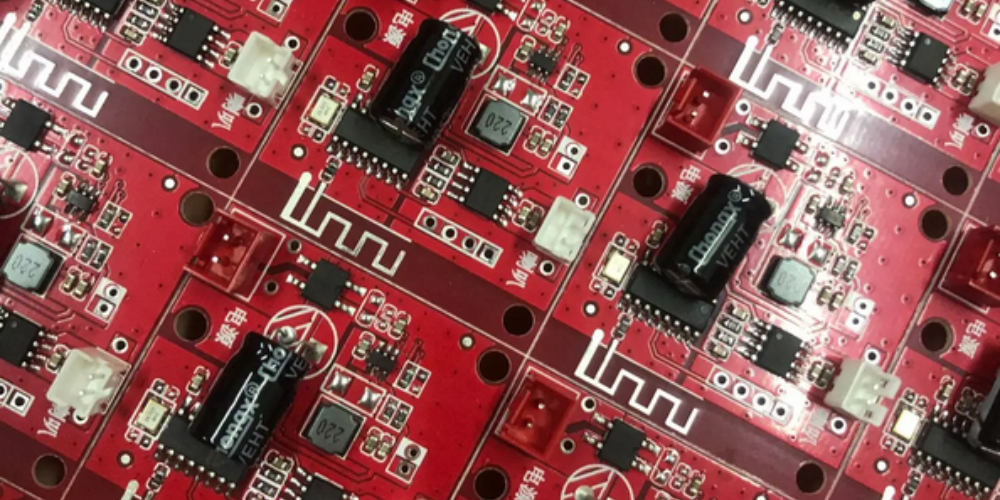

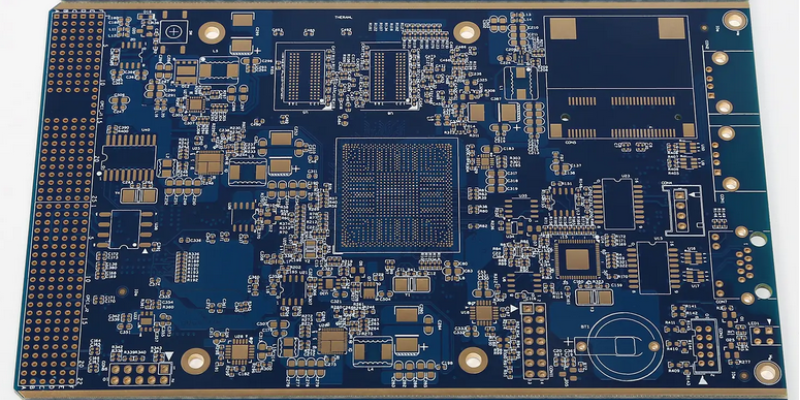

In the process of development, the company continues to provide professional, comprehensive and personalized solutions, such as PCB reworking and design, wafer foundry, chip decryption, PCB mass production, software and hardware development, prototype production and so on a one-stop service, so that customers’ needs are met both in quality and quantity, thus winning the unanimous praise of consumers. At the same time of technological innovation, Shenzhen RayMing Technology also continues to product innovation and service innovation.

The reason why Shenzhen RayMing Technology Co., Ltd. has developed into a leading enterprise in the industry is precisely because he regards innovation as the soul of the enterprise. As we all know, the speed of upgrading electronic products, for those who can not adapt to the innovation of the enterprise, will not be able to long-term invincible. Only like Shenzhen RayMing, depending on innovation as the soul of the enterprise, can survive in the fierce market competition and go farther and farther. The development of various industries, the size of policy support for the development of the product in the market can be said to be crucial, and sometimes even play a decisive role.

Shenzhen RayMing Technology Co., Ltd. is currently the only enterprise with high-tech qualification in the copy board industry, which has been specializing in PCB copy board and chip decryption technology services from its inception to now. RayMing has slowly formed a team of skilled, professional and efficient experts in research and development on the basis of the most advanced high-tech equipment, and has won unanimous praise within the industry and in the consumer market for its professional and responsible image of the industry.

The reason why Shenzhen RayMing Technology Co., Ltd. has become a leader in the industry is that it constantly innovates products and technology, takes the lead in the industry to break the negative label of “copying and plagiarism”, constantly leads technological innovation, and devotes itself to continuously improving technical research and development while paying more attention to the secondary development of the company’s products and the research and development of new products, always keeping itself in the business environment of constant innovation. We always keep ourselves in the business environment of continuous innovation.